EN

4

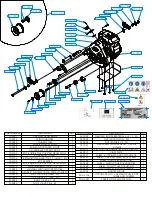

3.5.1

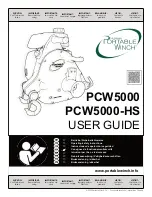

Winding the line around the capstan drum

1.

Start the engine and allow it to run idly for 30 seconds to warm up.

2.

Thread the rope thru the hook, over the pulley and then under the drum;

3.

Wrap the line around the drum (3 or 4 turns).

4.

Take the line behind the exit hook;

5.

Keep your distance from the winch (approx. 1 m) and pull

slowly and horizontally on the line until the line's slack is

taken up and you feel tension in the line;

6.

Inspect your installation to make sure that the anchoring of

the winch and the entry hook are aligned with the line;

7.

Check that the line is not rubbing against objects in its path;

8.

Increase the engine speed and pull on the line to start moving

the load.

3.5.2

Pulling

When pulling, position yourself so that you can see the winch and

the load. Pull on the line

HORIZONTALLY

. The tension you exert

on the line keeps the winch level.

3.5.2.1

If the line slips

If the line slips on the drum while you are pulling, add a turn of line

around the drum (4th turn). The engine will stall when the winch

reaches its maximum capacity. You should then review the

installation (add pulleys) or ''cradle'' the load (see next section).

3.5.2.2

To ''cradle'' the load

Pull until the engine nearly stalls and release the tension in the line.

Then return the tension to the line and repeat as required.

3.5.2.3

Taking a break during pulling

SLOWLY

release the tension in the line and allow it

to slide over the drum.

3.5.2.4

To maintain a load without releasing the tension

You must maintain the tension at the end of the line by holding it or

attaching it to a fixed object.

1.

Turn off the engine;

2.

Complete two turns of line around the exit hook before

removing the tension from your hands (Fig. 1 below);

3.

Then do two half-knots around the exit hook (Fig. 2 below).

3.5.2.5

To recommence pulling

Release some of the tension before restarting the winch's engine.

Firstly, undo the two half-knots. Allow the line to move slowly to

release the tension. Then, whilst holding the line in one hand,

restart the engine while pulling on the starter and increase the

engine speed. You can recommence pulling.

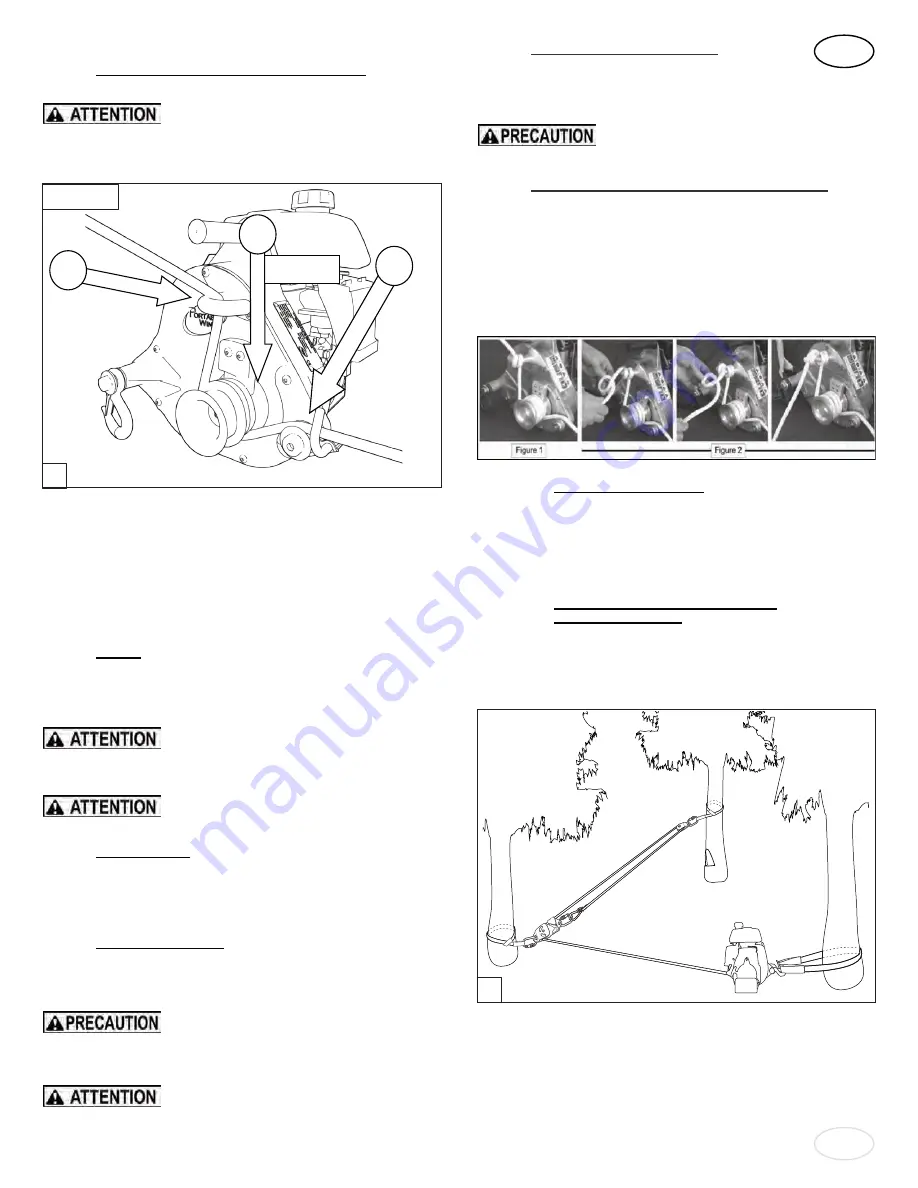

3.5.2.6

If it is essential to keep the tension

in the line at startup

You can use a blocker or a Prusik knot connected to your anchoring

point to maintain the tension in the line. You can also use a self-

locking pulley PCA-1271 or PCA-1272. They are particularly useful

for pulling rolling objects and for directional felling.

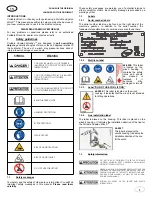

NEVER PLACE YOUR HANDS CLOSE TO THE LINE GUIDE,

CAPSTAN DRUM AND GUIDE PULLEY WHEN THE ENGINE

IS RUNNING.

2

PCW5000

3x /4x

4

3

2b

DO NOT WRAP THE LINE AROUND YOUR HANDS OR

YOUR BODY! ALSO, BEWARE OF BUILT-UP TENSION

CLOSE TO YOU AND MAKE SURE THAT YOU ARE A SAFE

DISTANCE FROM THIS ACCUMULATION.

KEEP AN EYE ON THE CAPSTAN DRUM DURING

OPERATION AND MAKE SURE THAT THE LINE DOES NOT

CROSS THE LATTER. IF THIS OCCURS, RELEASE THE

TENSION IN THE LINE, STOP THE ENGINE AND REMOVE

THE KINK.

BE CAREFUL WHEN USING THE LOAD ''CRADLING''

METHOD. THIS METHOD MAY CAUSE RAPID WEAR TO

THE LINE DUE TO THE HEAT CREATED ON THE DRUM.

IF THE WINCH PULLS THE LINE AND THE LOAD DOESN'T

MOVE (OFTEN WHEN A VERY LONG LINE IS BEING

USED), THE LINE STRETCHES AND THE BREAKING POINT

MAY BE REACHED CAUSING IT TO SUDDENLY COME

BACK ON TO YOU.

SLOWLY RELEASE

THE TENSION IN

THE LINE BUT BEWARE OF THE BUILT-UP TENSION: THE

LINE MAY QUICKLY GET AWAY FROM YOU CAUSING

BURNS OR TAKING YOU TOWARDS THE WINCH.

NEVER ALLOW THE LINE TO SLIDE ON THE DRUM FOR

MORE THAN A FEW SECONDS WHEN LOADED - THE

HEAT GENERATED BY THE FRICTION MAY MELT OR

DAMAGE THE LINE.

1