46

47

Slowly open the valve by turning the spindle anti-clockwise

until the required flow rate in l/min is achieved in the flow

meter window.

When adjusting the manifold flow rates care should be taken

to ensure that the adjustment spindle is not left with any of the

thread showing.

In order to carry out any maintenance to the installation it is

possible to isolate individual circuits by closing both the flow

and return ports, as shown in the diagram below.

NOTE:

The isolating valve fitted to the manifold flow meter

is not used for balancing purposes.

If it becomes necessary to close off a manifold completely,

this can be done by using a ¾” brass cap with a suitable rubber

washer insert.

Once all of the circuit flow rates have been adjusted the

system should be left to operate for a short period whilst any

remaining air is removed. Once this has been done the flow

rates should be re-checked and adjusted if necessary before the

actuator heads are fitted. If the actuator heads are not likely

to be fitted for a while then it is recommended that the blue

caps are used in order to protect the flow rate settings and

prevent any debris from entering the flow valve assembly.

IMPORTANT NOTE:

When using the PB970014 Modulating

Pump Unit to ensure that the primary boiler flow temperature

provided at the manifold is at least 15°C hotter than the

required manifold operating temperature. This is due to

the fact that this manifold uses an ‘injector method’ to mix

down the primary water. Furthermore, when balancing the

system with this particular manifold kit please ensure that the

modulating pump is set to a fixed head speed whilst making

any adjustments.

SYSTEM COMMISSIONING

Initial system filling

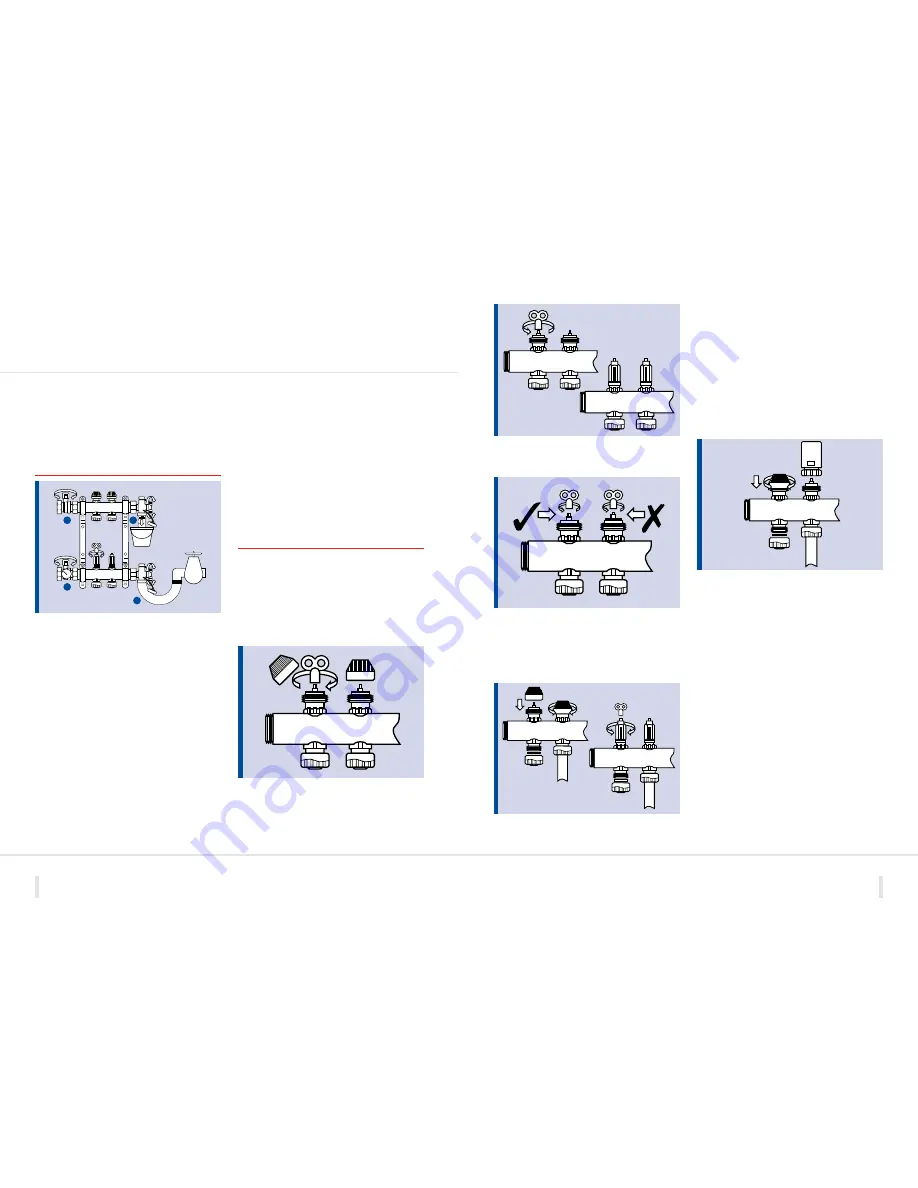

Close the manifold isolating valves (1) & (2). Connect a hose pipe

to the manifold return drain off point (4) and take to a drain.

Connect a second hose to the manifold filling point (3) and attach

to a mains cold water supply (3 bar max). The connections to

the manifold drain and fill points are ¾” BSP. Use flexible ¾”

tap connectors for the simplest method of connection.

Close all under floor heating circuits except one, by screwing

down the blue caps and closing the isolating valves situated on

top of the manifold flow meter. Flush the first circuit with mains

cold water until all of the air has been purged. Once this has

been done close the first circuit and repeat the process for all of

the other circuits on the manifold.

Once the system has been filled and purged of air, and before

any screed is laid, a system pressure test must be carried out to

confirm the integrity of the installation. It is recommended that

this test be done using a suitable hydraulic pressure test kit and

not with air.

NOTE:

The system pressure test should be carried out with the

manifold pump pack removed.

Close the manifold isolating valves and connect the pressure

test pump to the manifold flow rail using the ¾” threaded

connection on the filling/drain-off point (3). Pressurise the

system to 6 bar max and leave under pressure for 1 hour.

Once the pressure test is complete reduce the system pressure

down to 3 bar to protect the pipework whilst any screeding

process is carried out.

IMPORTANT NOTE:

Do not leave the system under pressure

during periods of extreme cold weather or when there is a risk

of freezing.

System balancing

Once the system is up and running it is necessary to balance the

system in accordance with the design data provided.

This should be done using the following method:

Ensure that the boiler and main system duty pump are operating

correctly and that sufficient heat input and flow rates are being

provided at the manifold(s).

Set the under floor heating controls to call for heat and

check to see that the two-port zone valve and manifold pump

are energised.

Remove the blue cap from the manifold flow port and,

using the bleed key provided, turn the flow adjustment spindle

clockwise to completely close the circuit.

Once installed, Polypipe under floor heating systems should be tested thoroughly

to ensure they are working effectively, including initial filling of the system

and system balancing. If you require any further information please contact

the Polypipe Technical Team on 01709 770000.

1

2

4

3