26

27

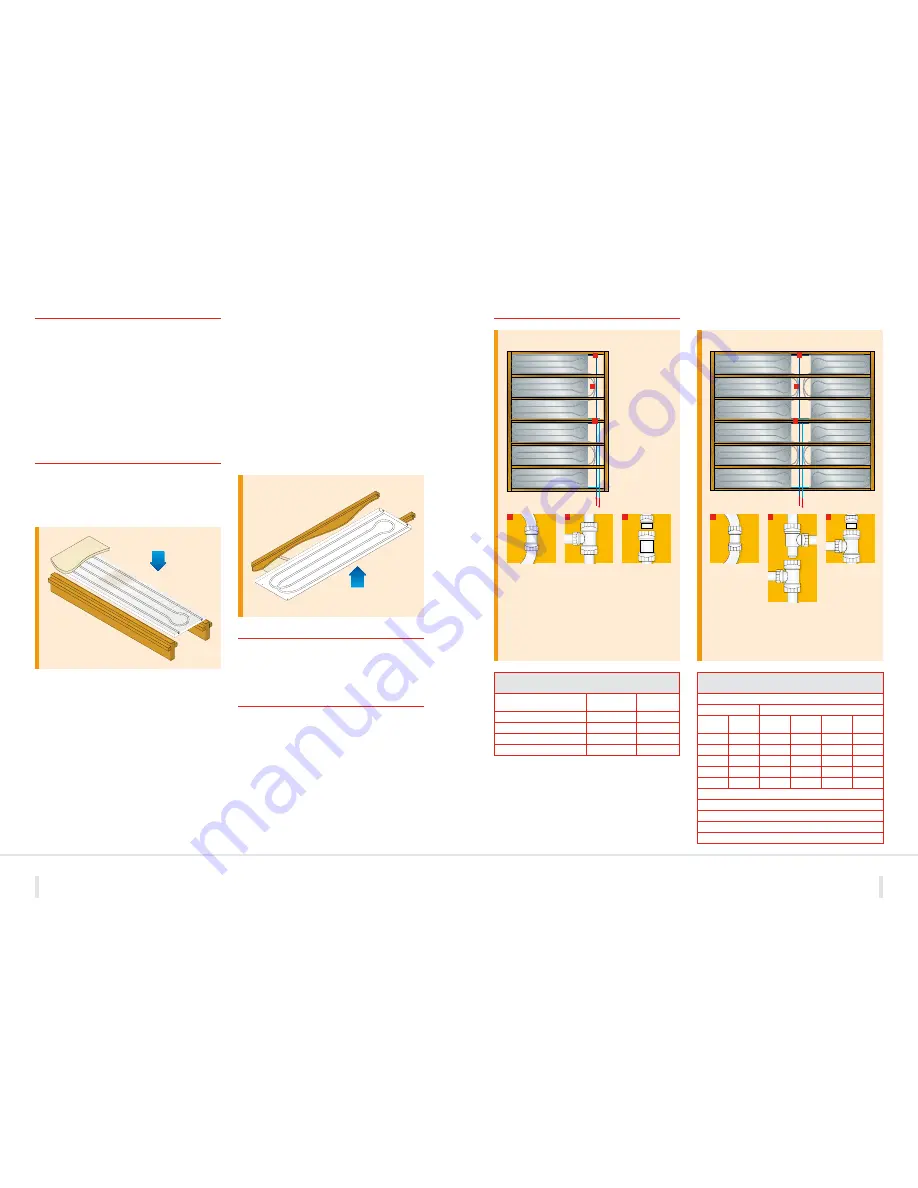

Panel layouts

Pre-installation requirements

Planning

Before installing MHP panels ensure you have planned out the

positioning of the required panels avoiding all other services such

as electrics, gas and water supply.

You will not need to do any specific preparation for the

installation in a new build property as there will be no ceilings

or floors in place.

For existing room refurbishment, you will need to take up your

floor if fitting from above or take down the ceiling if fitting from

below. Ensure that the area where the MHP panels are to be

positioned is free from any debris before commencing installation.

Installation

Installation from above

To install MHP panels from above simply fit support bearers to

each side of the joists. These support bearers should be positioned

30mm from the top of the joist and the MHP panel is then simply

laid on to these supports.

Installation from below

When installing MHP panels from below you will need to mark

out the positioning of the panels to ensure you have them

situated in the correct places for heating the room above.

Once you have checked the marked out positioning, the MHP

panels can be slotted into place and fixed to the underside

of the floor using 1¾” x 8 woodscrews with M6 x 30 dia washers.

It is advisable to use 6 fixings per panel ensuring you avoid the

moulded pipe marking on the underside of the panel and fix

each panel securely.

IMPORTANT NOTE:

Polystyrene can cause deterioration to cable

insulation when it comes into direct contact with it.

Always ensure that electrical cables are not in physical contact

with the MHP panels using tape or a polythene strip.

Finishing

Once you have connected your system up to the manifold and

tested it you can then finish the room by fitting the floor or ceiling

in the normal way depending on whether you have installed MHP

from above or below.

Testing

Where possible installations should be tested at 20°C to

18 bar pressure. Any installations once connected to the manifold

have a maximum test pressure of 6 bar.

Product Information

Product

Code

No of panels

per pack

MHP 490mm (W) x 2.0m (L)

MHP49020

5

MHP 490mm (W) x 1.3m (L)

MHP49013

5

MHP 380mm (W) x 2.0m (L)

MHP38020

5

MHP 380mm (W) x 1.3m (L)

MHP38013

5

Heat Output

Maximum floor area for flow and return 20m

2

Room at 20°C

Heat output per panel

Flow

Av. floor

MHP49020 MHP49013 MHP38020 MHGP38013

temp (°C)

temp (°C)

(W)

(W)

(W)

(W)

40

25.0

63

42

49

33

45

25.8

75

50

58

39

50

26.6

86

58

67

45

55

28.9

120

80

93

62

60

30.8

147

99

114

77

Approximate coverage required:

For 70W/m

2

room

= 80% coverage

For 50W/m

2

room

= 60% coverage

Connect up to 3 panels in series

Maximum coverage per circuit 20m

2

1 panel layout

15mm Polypipe flow and return

connections to manifold

15mm Polypipe flow and return

connections to manifold

Part No: PB010

10mm

Straight Coupling

Part No: PB010

10mm

Straight Coupling

Part No: PB1115

15mm - 10mm

Reduced Branch Tee

Part No: PB015

15mm

Straight Coupling

+

Part No: PB1815

15mm - 10mm

Socket Reducer

Part No: PB1115

15mm - 10mm

Reduced Branch Tee

+

Part No: PB1815

15mm - 10mm

Socket Reducer

Part No: PB1115

15mm - 10mm

Reduced Branch Tee

+

Part No: PB1215

15mm - 10mm

Reduced Branch

Spigot Tee

2 panel layout

1

1

2

3

2

3

4

4

5

5

6

6