- 14 -

2000_DE_Anbau_293

EN

ATTACHING TO TRACTOR

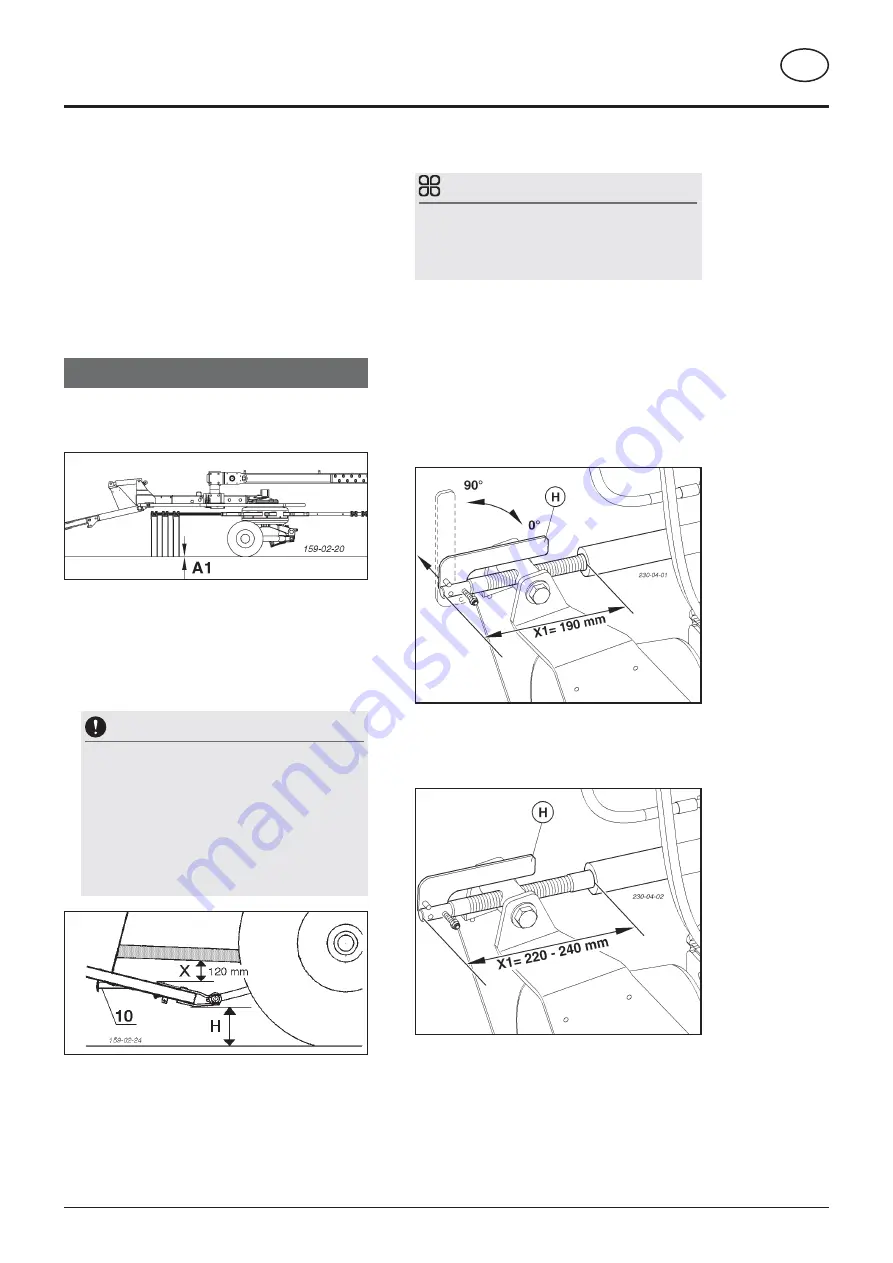

4. Adjusting rake height

TIP

The rake height dependent on the tractor and mount-

ing angle of the device. Reset the rake height if you

change tractors or alter the distance between the

cardan shaft and the toolbar.

Set the rake height

(X1)

with the threaded spindle

depending on whether or not the device is fitted with

"Multitast".

The machine is connected to the tractor and in headland

position (see above)

1. Swivel the lever (H) upwards (90°)

2. Loosen lock nut

3. Set the working height on the threaded spindle

a. Machines without "MULTITAST": X1 = 190 mm

Turn the threaded spindle until the thread is directly

aligned with the cylinder

a. Machines with "MULTITAST": X1 = 220 - 240mm

Twist the threaded spindle at a distance from the cylinder

4. Swivel down the lever (H) (0°)

5. Tighten the locking nut

In this position (0°) the threaded spindle is secured against

twisting.

Cutting to length procedure

- To adapt the lengths, hold cardan shaft halves next

to one another in the shortest operating position (L2)

and mark.

Shortest possible operating position (L2):

1. Lower hoist completely

2. Steering turned to lock.

(see adjacent illustration)

For details see chapter "Adapting the PTO shaft".

Preparations for initial use

1. Put the machine in the working position.

The working position is when the device is lowered and

the ground clearance of the tines (A1) is 10 mm - 0 mm.

2. Check the distance between the cardan shaft

and the toolbar

The distance (X) between the cardan shaft and the

toolbar must be sufficient to prevent collections between

the cardan shaft and the toolbar!

General standard gauge: 120mm

NOTE

Material damage in the event of a collision between

cardan shaft and toolbar.

If the terrain is extremely uneven, it is possible that

the general standard gauge (measured on a level

surface) may not be sufficient to prevent a collision.

Check the distance between the cardan shaft and the

toolbar at topologically sensitive points (e.g. round

ends) and adjust if necessary.

3. Check the position of the rotor tines

The position of the rotor tines (A1) should be somewhat

parallel to the ground; less inclination to the front is

permitted.