19

20

1

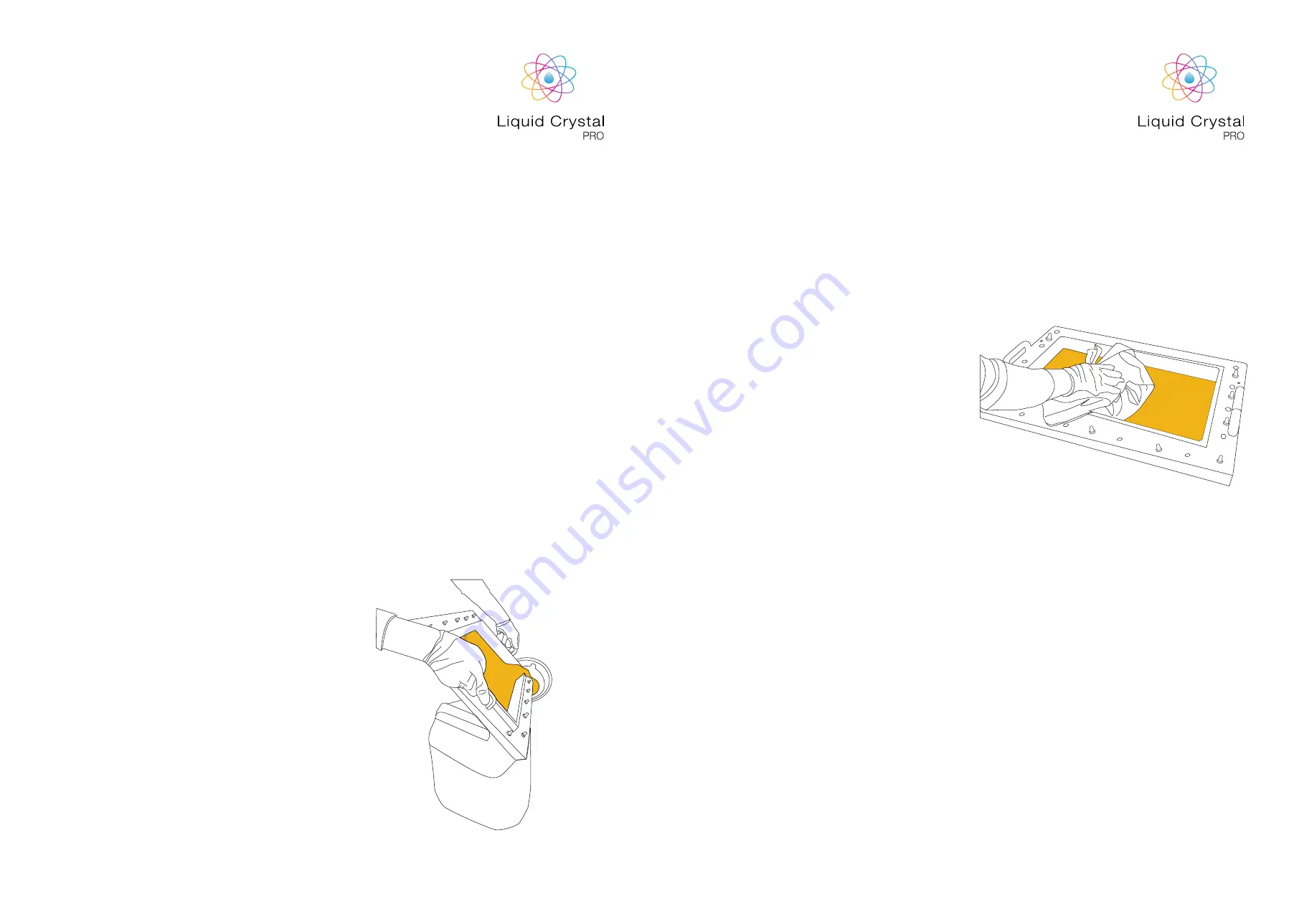

. Before starting a print on the Liquid Crystal Pro,

the vat should be emptied and cleaned. Wear

protective gloves. Ensure that the ambient

light level is not too high, don’t work in direct

sunlight and use low lighting where practical.

2. Prepare an area for cleaning the vat. You should

have a smooth, flat, clean surface with plenty

of space. Lay down two layers of paper towel

to protect the vat film from scratches and soak

up any spilled resin. Have a supply of paper

towels, a bottle of methylated spirits, and a bin

nearby. Do not work on a surface that could be

stained or damaged by contact with resin.

3. Position a 5 litre resin bottle near the printer on

a flat, stable surface and at a convenient height.

Be sure that there is enough space in the bottle

for all of the resin from the vat. Remove the lid

of the bottle and insert the funnel (supplied in

the accessory box) into the top. Place a clean

filter (supplied in the accessory box) inside the

funnel.

4. Remove the two vat bolts and set them aside.

Grip the vat firmly by the handles and lift it

carefully out of the printer. The vat will be

heavy, especially if there is a large volume of

resin remaining. Pour the resin gently into the

funnel from one corner of the vat. Pour at a

steady rate and be careful not to over-fill the

funnel. Resin will flow over the flange of the

vat; this is not a problem. Use a plastic card

to push resin down the vat film towards the

funnel.

5. When most of the resin has drained from the

vat, place it on the paper towels ready for

cleaning.When the funnel has drained, remove

it from the resin bottle and replace the lid.

5 EMPTYING AND

CLEANING THE VAT

6.

Use paper towels to clean up the resin on the

flange of the vat. Be particularly careful to clean

the resin out of the holes. If resin is allowed to

cure in the holes it can obstruct the nuts and

make it difficult to re-skin the vat. Methylated

spirits can be used to help clean the vat body.

7. Use paper towels to clean up any further resin

inside the vat. At this point it is important to

remove any pieces of cured resin that remain

in the vat. Anything left inside the vat could

cause damage to the vat or screen when the

printer is homed. It could also could prevent

successful printing. It is best not to apply

methylated spirits directly to the vat film.

8. Once the vat is clean, inspect the film for any

signs of damage or excessive wear. If there is

a puncture, or obvious damage, replace the vat

film. You can cover tiny holes in the vat film with

clear tape (eg. sellotape). If the vat is in good

condition, return it to the printer. Replace the 2

vat bolts (do not tighten).