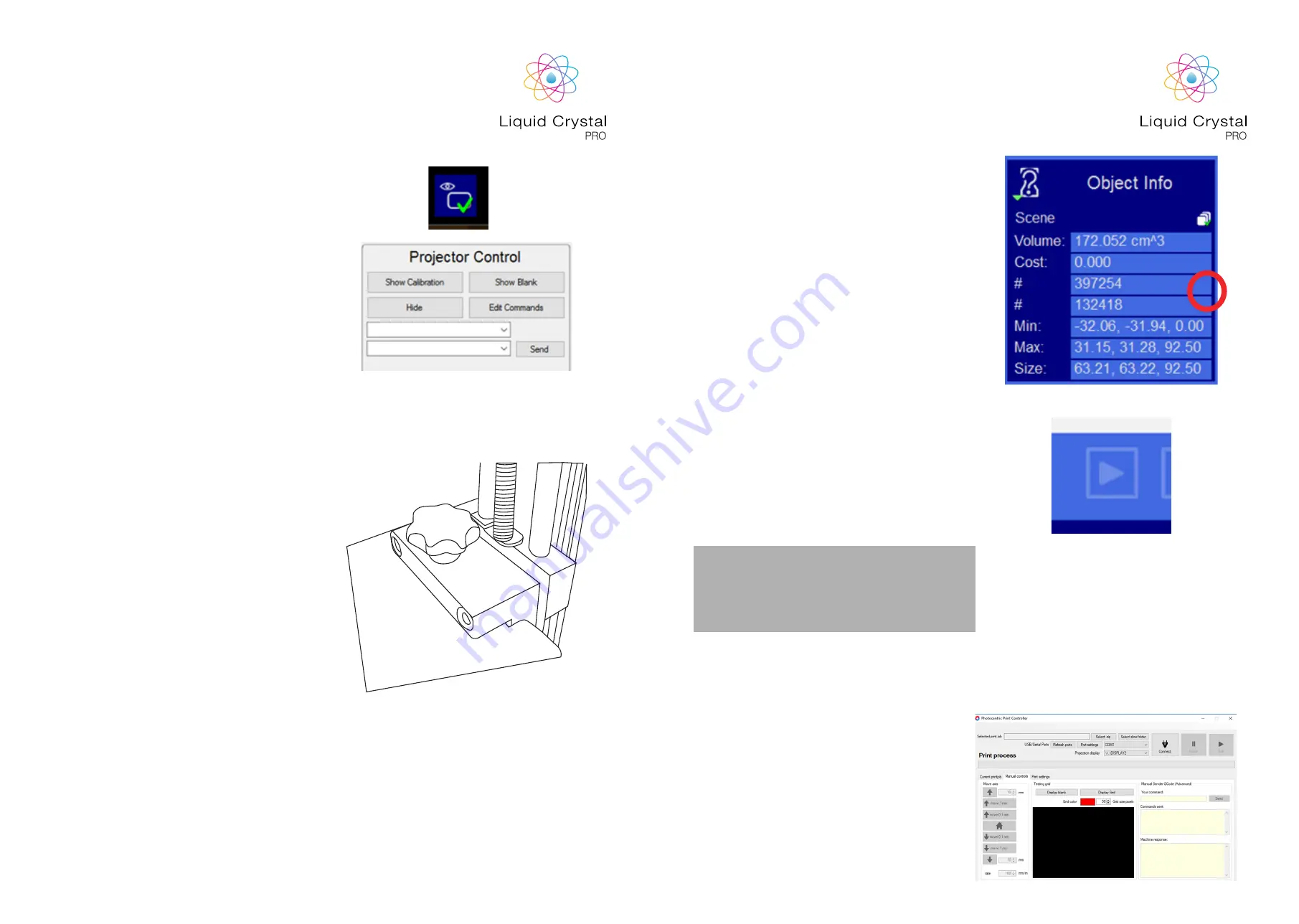

1. Check the first slice of your print on the printer’s

screen using the button below, in the ‘Slice View’

tab. (Use the push button on the front of the

printer to turn the screen on and off.)

2. Return the screen to black by pressing the ‘Show

Blank’ button in the ‘Control’ tab.

3. The vat should be inside the printer, empty and

clean. Use just the 2 front bolts to locate the vat

on the screen but do not tighten. The vat needs

to be free to move up and down. They should not

apply downward pressure to the vat. They are

only there to prevent the vat moving horizontally

or tipping.

4. Check that the drive carriages are at least 100mm

above the bottom of the rails. Slide the print plate

assembly into place in the printer. Push it back

against the stops. Tighten the two star knobs

that secure the print plate to the drive carriages.

5. On the print plate assembly, loosen the hex-head

bolts that secure the L brackets. They should be

loose enough to slide easily in the slots but not

more. A hex key is provided in the accessory

box.

6. Press the ‘Home’ button on creation workshop

(the door must be closed).

7. Wait for the printer to reach the home position.

If the print plate started in a very high position, it

may stop before reaching home. If so, press the

‘Home’ button again. Press down evenly on the

print plate with one hand and tighten the hex-

head bolts that secure the L brackets. Make sure

that all 4 corners touch the screen. If you press

the corners you should see white spots on the

screen. This is good and means that the platform

is flat against the screen. Once the platform is

homed and your first print is good, there is no

need to touch the L bracket hex head bolts

again. These bolts should be tightened firmly.

3. SETTING UP

A PRINT CW

15

16

8. Close the door and move the print platform up

10mm.

9. Check the volume of resin required in Creation

Workshop. Make sure the circled icon has the

green check mark to give the total volume. This

will include all items and any supports. Add 700

cm3 to this figure to allow for a full covering of

resin in the bottom of the vat during the final

layers of the print. You will need at least 1kg of

resin to cover the base and make your print.

10. Wear protective gloves and measure out the

resin. Be careful not to expose it to bright light

for more than a few seconds. Excessive resin will

make emptying the vat more difficult, insufficient

resin will prevent the print from completing

successfully. The maximum recommended

volume of resin in the standard LC Pro vat is

5000 cm3 (5 litres).

11. Carefully add the resin to the vat. Pour in the

centre of the print plate and it will drain through

the holes. Close the door and drive the print

plate down 10mm. Wait a few seconds for the

resin to settle. Press the ‘Print’ button in Creation

Workshop to begin printing.

Ref

Section 5.

The print time given in CW is not currently

accurate. On average Pro will print 1cm every

3 hours with firm resin or every 2hours 20 mins

with flexible resin.

3.1 SETTING UP A PRINT

PHOTOCENTRIC STUDIO

1. Open the print controller by clicking on the far

right icon of the top menu.

2. Press ‘Home Button’

3. Press Up arrow 10mm

4. Pour the resin into the vat. Refer to steps 10 and

11 above under section 3.

5. Press the downward arrow 10mm

6. Press Play button.