C

—

RECEIVER NOTES

1.

Mains supply voltage

This colour receiver has been designed to be used with a nominal

mains voltage of 240v. a.c. Engineers are advised that operating a

receiver on a mains supply which provides poor voltage regulation

(i.e., an isolation transformer rated at less than 500 watts) may

present difficulties in obtaining optimum convergence.

Note.

—

Once the receiver controls have been set-up, slight re-adjust-

ment may be necessary if the set is operated from a supply voltage

different from the initial setting-up voltage.

2. X-ray radiation warning

The voltages and currents on the cathode ray tube are higher in a

colour receiver than in a monochrome type, and as a result, the

X-rays produced will have a greater penetrating power and will

be present in larger quantities. In practice, this means that suitable

protection has to be built into a receiver in order to reduce the radia-

tion hazard to an acceptable level. It is important that personnel

involved in installation and servicing should be well aware of any

possible dangers.

The radiation problems are confined to X-rays generated by two

sou rce s:

(a)

The cathode ray tube

(b)

The extra high tension generator

During the development of the `G6' colour television chassis,

special attention has been given to these points. With the backplate

removed no significant radiation is present, and therefore the maxi-

mum dose rate is much less than the accepted danger level. This low

level of radiation is due to :

—

(i)

The absorbing power of the glass in the cathode ray tube.

(ii)

The C.R.T. metal cone shield provided for magnetic screening.

(iii)

The metal screening enclosing the E.H.T. generator (L.O.P.T.

assembly).

Provision is made on the E.H.T. generator so that the unit is in-

operative when the side cover of the screening can is removed. This

takes the form of an inter-lock switch disconnecting the H.T.

supply. On no account must this inter-lock be tampered with.

Line stabilisation control (R5040)

It is most important that this control is adjusted to the correct boost

voltage setting (see Adjustments). Any increase above this setting

will cause the E.H.T. voltage to rise, resulting in possible forward

X-ray radiation from the C.R.T. face.

3. Colour coding of H.T. supply leads

In order to assist service engineers in identifying the various H.T.

supply leads to different parts of the receiver, a system of colour

coding these leads is used which is shown below.

Supply

Lead colour

Voltage

H.T.2

Red

+285v.

H.T.2 (fused)

Red/Brown

+285v.

H.T.3

Red/Orange

+250v.

H.T.4

Red/Yellow

+230v.

H.T.5

Red/Green

+220v.

H.T.6

Red/Blue

+220v.

H.T.7

Red/Grey

—

120v. stab.

H.T.8

Black/Orange

+12v. stab.

H.T.9

Black/White

+18v.

4. Special trimming tool

A special star-shaped trimming tool is necessary for the alignment

of the tuner I.F. coil, and also for adjustment of certain other

cores. This trimming tool is available as part of the Philips

trimming tool kit 800/TX, and engineers are advised that any attempt

to adjust these cores with a non-standard tool may damage them.

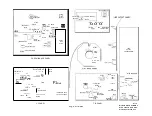

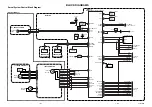

5. Use of the circuit diagram

(a)

The complete circuit of the `G6' single-standard colour tele-

vision receiver (less integrated tuner) has been drawn out on two

separate sheets accompanying this manual. The connecting leads

have been so arranged that the two halves of the circuit may be

permanently joined together with transparent adhesive tape if

required. H.T. points from the power supply circuits are shown

set in boxes, and an equivalent symbol is indicated at the particular

part of the circuit to which it is connected (see also note in colour

coding of H.T. leads

—

para. 3 above).

(b)

For component identification on the circuit, a grid refe

system is used. This has been arranged so that each sheet may

be

used either separately or joined together, the letters at the top of the

circuit running from A to S and the numbers at the side of each

diagram running down from 1 to 7. The grid location for all com-

ponents has been included in the Spare Parts List.

Where it has been found impracticable to show direct connections

between various parts of the circuit, e.g. the line pulse feeds

from L5505 and L5524, a grid reference has been included to assist

in locating the appropriate circuit connections.

(c)

In order to identify a particular component on the circuit

with its position in the receiver, a coding system for component

numbers is used. For instance, any component with a 2000 number

is located on the I.F. panel, and a component with a 5000 number

will be found in the line transformer assembly. The complete

coding system is as follows:

L O C A T I O N

Number

Valves &

Semicon.

Resistors

Capacitors

Coils

Main chassis and sub.

assemblies

1100

1000-1100

1000-1100

1500

C.R.T. base panel

1700

1000

1000

1500

Convergence unit

1200-1300

1200-1300

1200-1300

1600

Deflection, converg-

ence and degaussing

yokes

—

1700

1700

1700

I.F. Panel

2000

2000

2000

2000

Integrated tuner

3000

3000

3000

3000

Time Base

4000

4000

4000

4000

Line transformer

assembly

5000

5000

5000

5000

Chroma. panel

7000

7000

7000

7000

6. Connecting plugs and sockets

The plugs and sockets used for interconnecting assemblies are

colour coded to enable service engineers to identify where each is

fitted to the main chassis. This takes the form of a coloured ring

around the plug on the appropriate connection panel, and a

similarly coloured sleeve marker around the leads into the respec-

tive socket.

Note.

—

Sockets should never be removed from the plugs by pulling

on the leads, since this practice may lead to the pins within the

sockets being damaged.

Page Four

Содержание G22K511

Страница 3: ...G22K511 G25K512 Page Two ...

Страница 12: ...Page Ten ...

Страница 14: ...Page Eleven ...

Страница 19: ...Page Fifteen ...