4.

Alignment of the inter-carrier sound I.F.

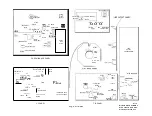

Apply the sweep generator to

TPI

via the terminating pad (see

Fig. 9) and the oscilloscope to TP3. Set R2073 to its mid position,

then trim L2526, L2504, L2503, L2643/4 and L2645 for maximum

height and symmetry centred on 6.0MHz. Reconnect the oscillo-

scope to TP4 and trim L2628/9 for a symmetrical 'S' curve of

maximum amplitude. Finally reset R2073 (see para. 5 below).

5.

Adjustment of ratio detector balance control R2073

Apply a 6.0MHz amplitude modulated signal to TP1 and connect

the oscilloscope to TP4. Adjust R2073 for minimum output.

6.

Setting of L2573/4 neutralising coils

The adjustment of L2573/4 is preset during manufacture and should

not be disturbed during alignment. However, in the event of

accidental movement of the core, the adjustment may be made as

follows:-

Set the core flush with the top of the coil can, then screw the core

in 5 turns and seal with soft wax.

7.

Chroma. bandpass alignment

Short-circuit pins 4 and 5 of V7008 and connect the anode of X7326

to chassis. Connect a 6v. battery from pin 2 of V7003 to chassis

(positive terminal to chassis). Open-circuit solder link

B

(see

Fig.

33) and apply the sweep generator to TP2 via the terminating pad.

Connect the oscilloscope to TP6 via the detector unit shown in

Fig. 11. Trim L2773 for minimum response at 6.0MHz. Trim

L7517/8, L7508/9, L7506 and L2775 for maximum response with

correct curve shape and bandwidth centred on 4.43MHz (see

Fig. 13). Finally, resolder link

B

on the print, remove the bias

battery and short circuits from X7326 and pins 4 and 5 of V7008

then check the adjustment of R7179 and R7206 (see section H,

paras, 22 and 23).

Note.

When alignment of the chroma. bandpass

circuit has been

completed, the decoder alignment must be checked, particularly

the setting of L7559/60 and L7561.

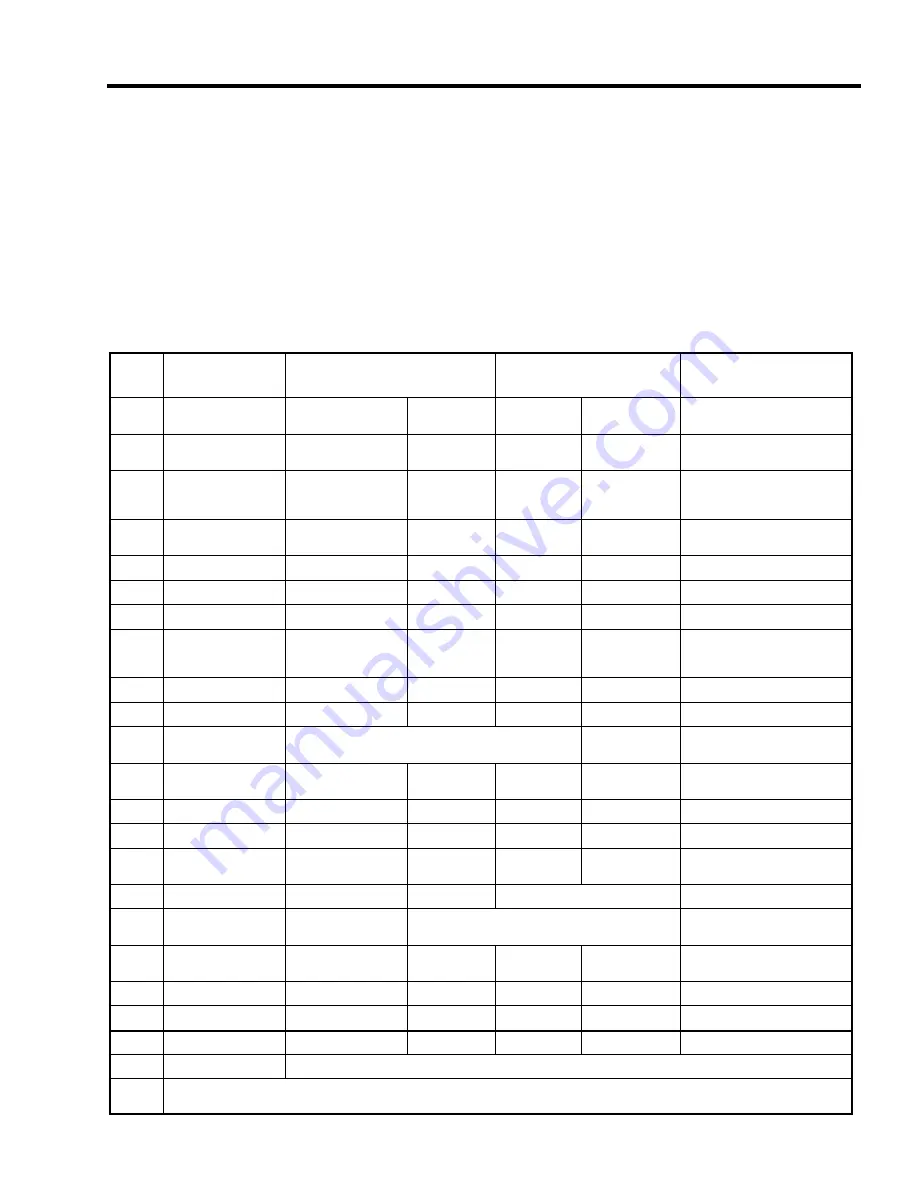

I.F. ALIGNMENT TABLE

Input from

C20.4I

sweep generator to

and turn R2092 fully

clockwise.

TP7 (tuner injection point) via the

terminating

pad (see Fig. 9). Connect

a short-circuit across

Circuit

Marker

frequency

Damp

to chassis

Trim

Trim for

Oscilloscope

connection to

I.

Tuner I.F.

36.0MHz

-

L3404

Max.

TP5 via damper/

detector (Fig. 10)

2.

Ch. I rej.

-

-

L2586

Unscrew core

level with

top of can

-

3.

Sound ledge

atten.

33.5MHz

-

L2555

Min.

TP5 via damper/

detector (Fig. 10)

4.

I st vis. I.F.

37.0MHz

-

L2554

Max.

,,

5.

2nd vis. I.F.

37.0MHz

-

L2564

Max.

„

6.

Ch. I rej.

41.IMHz

-

L2783

Min.

„

7

.

„

41.5MHz

L2783

(point A

Fig. 33)

L2586

Min.

„

8.

1st vis. I.F.

39.0MHz

-

L2554

Max.

„

9.

2nd vis. I.F.

37.0MHz

-

L2572

Max.

„

10.

Check response curve

shape.

against Fig. 15 and, if necessary, readjust L2572, L2554 L2564 and L3404 to obtain the correct curve

11.

Sound ledge

filter

33.7MHz

-

L2603

Min.

TPI

12.

3rd vis. I.F.

37.0MHz

TP5

L2598

Max.

71

13.

,,

37.0MHz

-

L2596

Max.

,,

14.

Luminance

detector

37.5MHz

-

L2620

Max.

t,

15.

„

37.5MHz

-

L2621

Max.

„

16.

Check response curve

shape and limits.

against Fig. 12 and, if necessary, readjust L2598, L2596, L2620 and L262I to obtain the correct curve

17.

Chrominance

detector

35.IMHz

-

L2744

Curve

Fig. 14

TP2

18.

„

39.5MHz

-

L2745

, ,

9 t

19.

"

37.2MHz

-

L2746

Min.

20.

„

37.9MHz

-

L2747

Min.

,P

21.

Check response curve against Fig. 14 and, if necessary, readjust L2744-47 to obtain correct curve shape and limits.

22.

With C2041 short-circuited and no signal input, connect a voltmeter across R2086 and adjust R2092 for a reading of 2.4 volts.

Page Thirteen

Содержание G22K511

Страница 3: ...G22K511 G25K512 Page Two ...

Страница 12: ...Page Ten ...

Страница 14: ...Page Eleven ...

Страница 19: ...Page Fifteen ...