19.

Release of tuner push-buttons

In the event that all four push-buttons have been accidentally

pressed in simultaneously, they may be released by pressing in the

second button from the left (BBC2) still further.

20.

A.M. rejection (R2073)

Tune in the receiver and adjust R2073 for minimum buzz on

sound.

21.

Preset A.G.C. (R2092)

Connect a voltmeter across R2086 and short-circuit C2041. Then,

with no signal input, adjust R2092 to obtain a reading of 2.4

volts.

22.

Chroma. A.G.C. adjustment (R7179)

Adjust the receiver to give a normal colour picture, then turn the

colour control to maximum. Set R7179 to give slightly more than

correct saturation. Detune the receiver slightly to check that the

colour killer circuit operates before luminance is lost. (If not,

make a slight readjustment to R7179),

23.

Chroma. tracking adjustment

(R7206)

The correct setting for R7206 should ensure that as the contrast

control is varied, the saturation will remain in step. Adjust R7206

until it is found that both luminance and saturation levels track

together over the range of contrast settings.

In the event of transistor or valve replacement, the following pre-

set control adjustments must be checked and re-adjusted if neces-

sary.

Transistor/valve

Control

T2142

R2092

T7012

R7173

T7015

L7634

V1706, V2001

R7285, R1279, R1280,

R1281, R1077, R1080

V4001

L4501/2, R4071, R5040,

R5053

V4002, V4004

R4098, R4105, R4101,

R4115, R4121, R4120

V5001,

V5004,

V5002,

V5005

V5003,

R5040, R5053, R5045,

R7301

V7001, V7002, V7003

R7179, R7206

V7005, V7006, V7007

R7173, R7245, R7236

V7008

L7624-6, R7168

V7009

L7651/2, L7638

I

—

CONVERGENCE

General

Before attempting any adjustments of convergence, the receiver

must be allowed to warm up for at least 20 minutes, and all

normal adjustments of height, width, linearity and raster

correction must be completed.

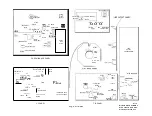

Note: In the following notes on purity, static and dynamic conver-

gence, the numbering of the controls relates to Fig. 8. The diagram

attached to the convergence panel may be employed in conjunction

with these instructions, using the waveforms to help explain the

function of each control.

Degaussing

The receiver is fitted with an automatic degaussing circuit which

operates each time the set is switched on from cold. However, in

cases where the C.R.T. and/or associated metal parts

have been

subjected to extra strong magnetic fields, it may be necessary to pass

an external degaussing coil across the C.R.T face and

in each

corner before purity/convergence adjustments are carried out.

At no time whilst using an external degaussing coil

should it be al-

lowed

to come closer to the face of the C.R.T. than is necessary for

complete degaussing, otherwise permanent damage may

be caused to

the shadow-mask plate inside the tube.

Notes:

1.

When readjusting the purity ring magnets, care should be

taken that no undue force is exerted on the rings which may con-

sequently damage the plastic retaining clips.

2.

In common with normal servicing practice, the receiver should

not be switched off and on again in rapid succession when warmed-

up. This may not only adversely affect valve heaters, etc., but it is

possible that static convergence errors may occur.

3.

All purity, convergence and grey scale adjustments should be

carried out under subdued lighting conditions.

Purity

1.

Switch off the green and blue guns (depress switches 17 and 18)

and remove the receiver signal input (pull out the tuner output lead

on the I.F. panel). Purity should be adjusted on a plain red raster,

using only average brightness.

2.

Cancel the purity ring magnets by setting the notch A in each

ring in line with the other (see Fig. 7).

3.

Loosen the wing nuts B (see Fig. 7) and push the deflection

coils fully forward. The red area should now be moved to the

centre of the screen by adjusting the purity magnets.

4.

Move the deflection coils backwards until the red area fills the

whole screen. Small errors may be overcome by a further slight

adjustment of the purity magnets.

5.

Switch off the red gun (19) and switch on the green gun (18).

Check that the whole of the screen is green.

6.

Switch off the green gun (18) and switch on the blue gun (17).

Check that the whole of the screen is blue. Finally, tighten the wing

nuts B.

Spot

Deflection Coils

Blue Shift

A

Green Shift

Convergence

Assembly

7 :

0 a

SD3295

Blue Lateral

Shift Magnet

Fig. 7. Deflection assembly

Red Shift

Purdy Magnets

Содержание G22K511

Страница 3: ...G22K511 G25K512 Page Two ...

Страница 12: ...Page Ten ...

Страница 14: ...Page Eleven ...

Страница 19: ...Page Fifteen ...