7

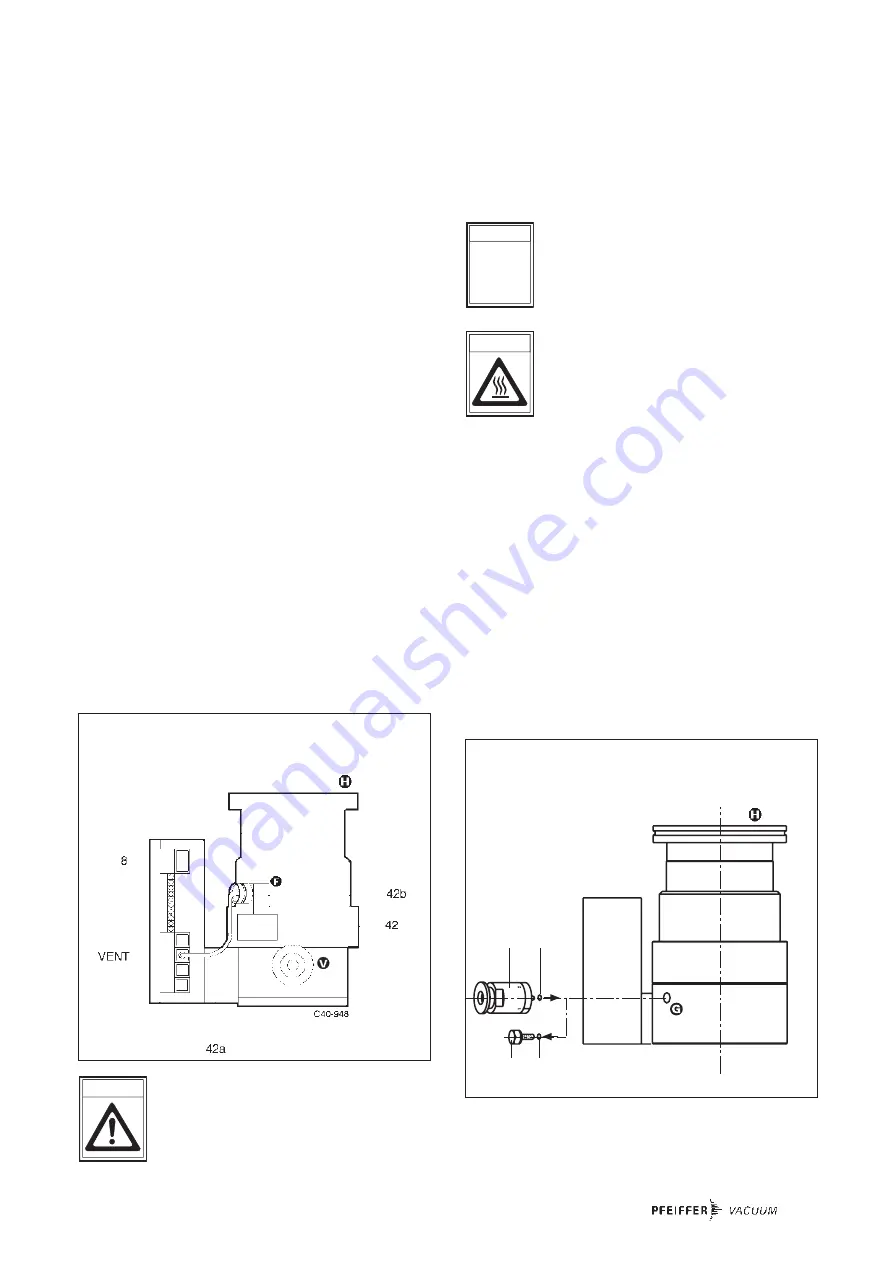

Connecting the venting valve

8

Electronic Drive Unit TC 600

42

Venting valve TVF 005

42a Control lead venting valve/TC 600

42b Plug

The maximum pressure at the venting valve is

1.5 bar absolute.

Please refer to Operating Instructions PM 800 507 BN for

details on Venting Valve TVF 005.

CAUTION

3.4. Connecting The Cooling Unit

Turbopumps TMH 071 P/TMU 071 P can optionally be

provided with enhanced convection cooling, air cooling or

water cooling.

The turbopumps must be operated with air or water cooling

where the fore-vacuum pressure is increased (> 0.1 mbar)

and/or operations with gas loads.

Use and installation:

– For water cooling please refer to Operating Instructions

PM 800 546 BN.

– For air cooling please refer to Operating Instructions

PM 800 543 BN.

– Permissible installation positions for the cooling unit

where convection cooling is involved please see

Section 9.1. ”Dimensions Diagram”.

3.5. Connecting The Venting Valve

The Venting Valve TVF 005 provides automatic venting in the

event of a power failure and switching off.

Fitting the venting valve

➡

Unscrew the venting screw from the venting connection of

the turbopump.

➡

Screw in venting valve 42 with seal (USIT ring) on hexago-

nal SW 14.

Electrical connection

➡

Plug control lead 42a into the connection ”VENT” of the

TC 600 (8) on the turbopump.

The venting mode of the venting valve is selected via the DCU

or Serial Interface RS 485.

3.6. Connecting The Casing Heating Unit

The attainment of final pressures is accelerated when turbo-

pumps and vacuum chambers are baked out.

The heating duration is dependent on the degree of dirt and

on the required final pressure level. The heating duration

should be at least 4 hours.

Where casing heating is involved the

turbopump must be water cooled.

High temperatures are generated when the tur-

bopump is baked out. There is a danger of

burns resulting from touching hot parts, even

after the casing heating has been switched off.

Ideally, the heating sleeve.and the pump casing

should be insulated during installation. Do not

touch the heating sleeve and the pump casing

during the baking out process.

Please refer to Operating Instructions PM 800 542 BN for

details on the casing heating unit and its installation.

3.7. Connecting The Sealing Gas Valve

To protect the pump, particularly where corrosive or dust pro-

ducing processes are involved, it is necessary to use sealing

gas.

Connection is made via the sealing gas valve (please see

“Accessories”).

WARNING

☞

PLEASE NOTE

Please refer to Operating Instructions PM 800 229 BN for

details on installing the sealing gas valve and adjusting the

sealing gas flow.

66 66a

9 15

Connecting the sealing gas valve

9

Locking screw sealing gas connection

15

Dichtung

66

Sperrgasventil

66a Dichtung