Required consumables

● Operating fluid of the vacuum pump

Required aids

● Funnel (optional)

MAX

MIN

1

3

4

2

Max.

Min.

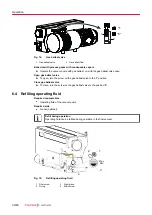

Fig. 6:

Filling the operating fluid

1 Filler screw

3

Sight glass

2 O-ring

4

Drain screw

Filling the operating fluid

1. Unscrew the filler screw.

2. Fill the operating fluid according to the sight glass:

3. Screw in the filler screw again.

– Be careful with the O-ring.

4. Seal the vacuum connection.

5. Start the vacuum pump.

6. Operate the vacuum pump for approx. 5 minutes.

7. Switch off the vacuum pump.

8. Wait approx. 1 minute until the operating fluid has accumulated in the operating fluid separator.

9. Check the fill level.

– The correct fill level is between the Min/Max markings or within the ring mark on the sight

glass.

10. If necessary, fill more operating fluid in case the fill level is incorrect.

5.5 Connect the oil/water heat exchanger

NOTICE

Vacuum pump damage caused by different cooling characteristics

For applications with short switching cycles or increased ambient temperature, there is a risk of dam-

aging the rotor after switching off temporarily.

► Always switch the oil / water cooling off together with the vacuum pump.

► For checking the cooling water flow, use a solenoid valve that only opens when the vacuum

pump is switched on.

Installation

22/60

Содержание HENA 201

Страница 1: ...OPERATING INSTRUCTIONS EN Translation of the Original HENA 201 251 301 301 S Rotary vane pump ...

Страница 59: ...59 60 ...

Страница 60: ... PD0087 ed C Date 1910 P N PD0087BEN ...