JOb

CLEANING AGENT*

COmmENTS

routine Cleaning

Soap, ammonia, detergent

apply with sponge or cloth.

Can be used on all finishes.

Fingerprints and smears

areal 20, Lac-O-nu, Lumin Wash,

Provides barrier film to minimize

O’Cedar Cream Polish

fingerprints. Can be used on all finishes.

Stubborn stains and

allchem Concentrated Cleaner,

rub lightly, using dry or damp

Discolorations

Samae, twinkle, Zud restoro,

cloth in the direction of polish

grade F or FFF italian Pumice,

lines on the stainless steel.

Whiting or talc, Liquid nu Steel,

Copper’s or revere Stainless Steel

Cleaner, Lumin Cleaner, Sta-Clean,

Cameo Copper Cleaner, allen Polish

highlite, Penny-brite, Copper brite

5

Perlick is committed to continuous improvement. therefore, we reserve the right to change specifications without prior notice.

general information

Form no. Z2279

rev 08.01.07

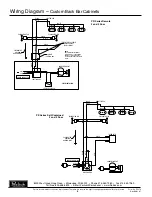

Refrigeration and Temperature Control

the cabinet is equipped with a heavy-duty

refrigeration system designed to automatically

maintain a storage temperature of 36-41 degrees F.

the control is factory set at 38 degrees F.

Adjusting the temperature

the temperature control is inside the cabinet on

the left-hand side of the evaporator fan panel

assembly. You will need a screwdriver to turn the

adjusting screw. Make small adjustments until the

desired temperature is achieved.

■

Colder Temperatures:

turn the adjusting screw clockwise (to the right).

■

Warmer Temperatures:

turn the adjusting screw counterclockwise

(to the left).

■

Temperature Control “Off”:

turn the adjusting screw completely counter-

clockwise to the “O” position until a click is

noted.

the condenser fan motor turns off and on with

the compressor. the evaporator fan motor is on

all the time.

NOTE:

Cabinet temperatures lower than 34° will not

allow for proper defrosting of the evaporator coil. if

defrosting is necessary, turn the control knob to the

OFF position until coil is defrosted.

Cleaning the Cabinet

Use a mild detergent and water to clean the inside

and outside of the cabinet. Dry thoroughly. never

use a scouring pad or abrasive cleanser.

NOTE:

an industrial strength, commercial cleaner

can be used to clean the outside of painted

cabinets.

Cleaning the Condenser

Use a long handled, stiff brush to clean the dirt

from the front surface of the condenser. Keeping

the condenser free from dust and dirt will ensure

efficient operation.

CAUTION:

Do not bend the fins while brushing the

front of the condenser.

Condenser

the condenser (located behind the front grille

cover) should be inspected every 30 days and

cleaned, if necessary.

Failure to keep the condenser clean will cause a

loss in condensing unit efficiency.

1

2

3

4

5

6

OFF

COLD

COLDer

Recommended Cleaning Agents

*

Use of propriety names is intended only to indicate a type of cleaner and does not constitute an endorsement.Omission of

any proprietary cleaner does not imply its inadequacy. All products should be used in strict accordance with instructions on

the package.

nOte: Do not Use Steel Wool or Scouring Pads to clean stainless steel.