1/01 E Service Instructions

11

Machine Size 92 (Fig. 8)

The clamp is guided by pre-

tensioned roller guideways, i. e. it

is play-free. Therefore, readjust-

ing is not necessary.

If any wear is found due to long

and hard use of the machine, the

roller guides should be replaced.

For this purpose, proceed as fol-

lows:

• Support clamp 1 by wooden

wedges, for example.

• Pull out pins 5 and slacken

screws 6 of knife beam guide strip

7.

• Remove roller guideway 4 by

slackening screws 8. Observe

the assignment of shims 3.

• Slightly tighten the new roller

guideways with their associated

shims 3 by means of screws 8.

• Re-pin knife beam guide strip 7

and tighten with screws 6.

• Check air gap a on the roller

guideway. Gap a should be

0.5 mm when the roller guideway

is properly pre-tensioned.

• If necessary, re-tension the outer

roller guide strip by means of

screws to be introduced into the

tapped holes in knife beam guide

strip 7 until gap a is obtained.

Then, tighten the roller guideway

with screws 8.

Remove the wooden wedges and

check the clamp for free move-

ment by pressing the pedal.

Machine Sizes 115/132 (Fig. 9)

• Slacken lock nuts 5 on adjusting

screws 6.

• Slightly slacken screws 7 on

adjusting strip 8.

• Reset adjusting strip 8 against

guide blocks 9 by adjusting

screws

6

until play a between the

adjusting strip and the guide block

is < 0.05 mm.

When performing this adjustment,

ensure that guide blocks 9 rest

on the opposite side of guide strip

10. For this purpose, press the

clamp towards the knife.

• After completing the adjustment,

tighten the screws and nuts and

check the play over the entire

clamp stroke with a feeler gauge.

The lateral play (face play) should

be b = 0.1 + 0.05 mm.

For this purpose, adjust support-

ing screws 11 with screws 12

slightly slackened until play b is

obtained between guide strip 10

and guide block 9. Tighten screws

12.

Clamp Parallelism

with the Cutting

Table

In the factory, the clamp is aligned

in parallel with the cutting table

surface.

This can be checked by pre-

clamping with paper strips put

under the left and right sides of

the clamp.

If correction should be neces-

sary, proceed as follows:

Machine Sizes 76/92

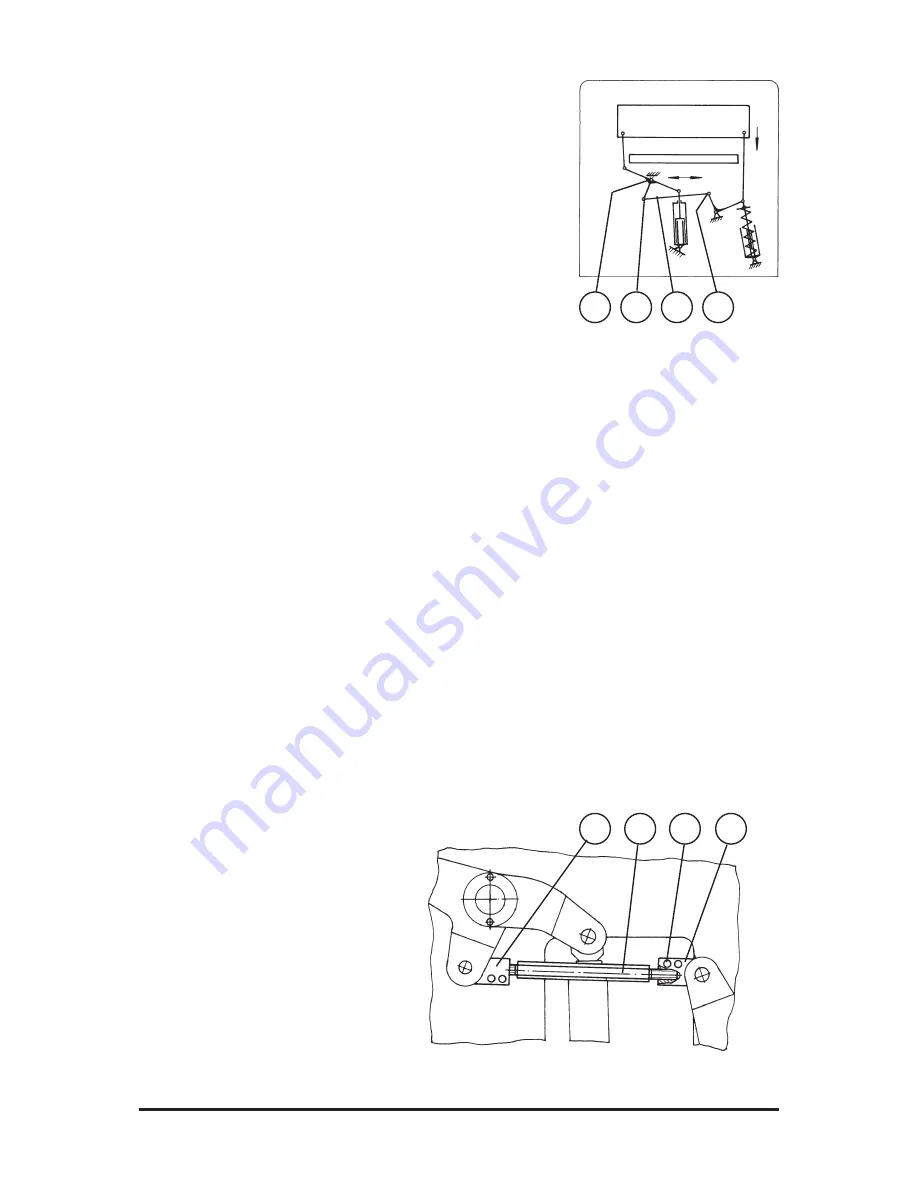

Fig. 10 shows the clamping prin-

ciple for machine sizes 76 and

92.

Machine Size 76 (Fig. 11):

• Remove the hydraulic system

front paneling under the cutting

table.

• Slacken clamping screws 1 in

pusher rod eyes 2 and 3.

• Turn pusher rod 4 as follows:

- Increasing the distance between

the pusher rod eyes moves down

the clamp on the right.

Fig. 10

Fig. 11

5

2

4

3

3

4

1

2

Содержание 115 TV

Страница 5: ...1 01 E Service Instructions 5 Fig 2 ...