17

PENTALIFT EQUIPMENT CORPORATION

M086R06

December 8, 2017 10:37 AM

LDL Dock Lift Owners Manual

8. Check the hinged bridge to ensure that its stops are not

damaged, allowing it to droop more than 45 degrees below

horizontal, check the hinge spools for cracks and or broken

welds.

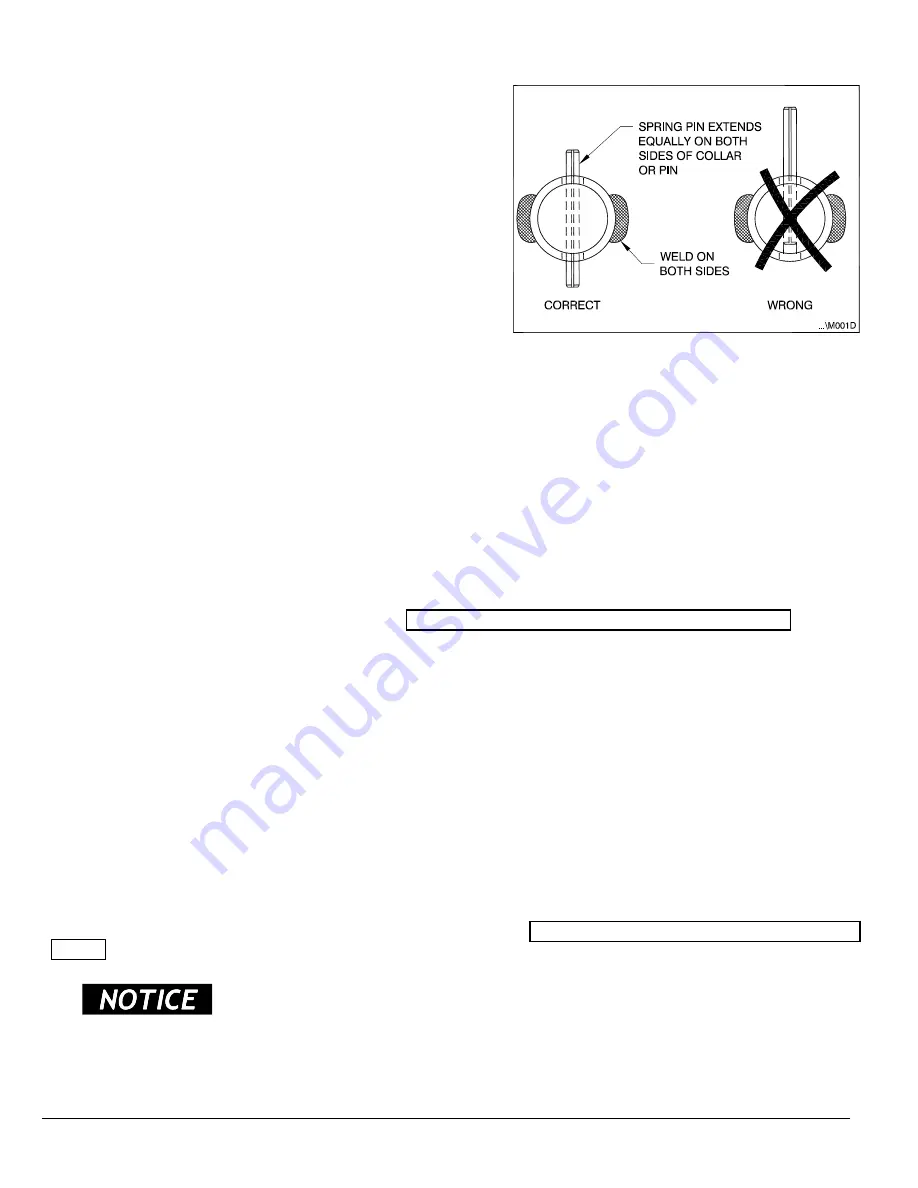

Check all spring pins, items 2, 29 and 35 in Figure 13, page 19, to

confirm they are not damaged and that they are properly inserted.

Confirm that all welds on the spring pin collars are intact. (See

Figure 11, page 16)

Ensure that any specified interlocks (e.g. overhead doors,

restraints) are fully functional.

Ensure the toe sensor (if equipped) is functional by raising the lift

to full height and lifting the toe sensor bar under each of the toe

sensor limit switches (there are normally 4 switches). Confirm the

unit does not lower with the toe sensor bar raised. Repeat the lifting

on each of the limit switches and confirm the unit will not lower when

the bar is lifted under any of the switches.

NOTE:

The toe sensor option is an electrical safety device with an actuator

suspended beneath the platform which halts downward travel of the dock lift if it contacts with an obstruction. (This feature

is not functional in the event of hydraulic failure.)

Figure 11: Spring Pins

Hydraulic Oil:

Weekly:

Once a week, or after repetitive operation, the lift should be raised to its full height. This will get rid of cylinder oil

seepage build-up and lubricate the upper cylinder barrel.

Monthly:

For ease of maintenance, lifetime lubricated bushings have been used on all rollers, leg pivot points as well

as the upper cylinder pivot. However, units installed outdoors or in wet and dirty environments should be

recommended lubrication

service interval is every 30 days

or at a greater frequency as required in severe

environments.

Dexron III Automatic Transmission Fluid

is recommended.

The oil level should be checked once a month. When the dock lift is fully lowered, the oil level in the reservoir of a

1 or 3 hp power unit should be approximately 2 – 3 inches from the top. A 5 hp or higher power unit should have

the oil in the reservoir filled to the full mark on the sight gauge. The oil should be changed once a year under

normal operating conditions. The standard replacement Hydraulic Fluid is DEXRON III Automatic Transmission

Fluid which has an operating range of -10°C (14°F) to 50°C (122°F). If the hydraulic oil is non-standard, check

the hydraulic reservoir for fluid label which will specify the particular fluid requirements. It is strongly urged that a

maintenance log be maintained with the dates of monthly inspections, the name of the inspector and results of the

inspection.

Seasonal or semiannual maintenance:

Change hydraulic fluid for ambient temperature changes if appropriate. Check the

fluid reservoir to see if there is any evidence of accumulated condensation creating water contamination. The fluid

will appear “milky” and light pink in color. Water accumulation will damage the hydraulic pump.

Dock lifts also require grease at the base of the hydraulic cylinders; See “Figure 12: Lubrication Oil and Grease Points” on

The standard hydraulic oil supplied with the equipment is good from -20º C (-4ºF) minimum

to +54ºC (+129ºF) maximum unless otherwise specified on the equipment order. When

operating the equipment in temperatures lower than -20ºC (-4ºF) or above +54ºC (+129ºF), the pump may create

cavitation, causing permanent damage to the power unit. This will void all warranty. The standard replacement

Hydraulic Fluid is DEXRON III Automatic Transmission Fluid which has an operating range of -10°C (14°F) to

50°C (122°F). If the hydraulic oil is non-standard, check the hydraulic reservoir for fluid label which will specify the

particular oil requirements.