Environmental requirements for installation

The place where the machine is to be mounted

must meet the following:

•

Flat, horizontal and stable floor, preferably in

concrete or covered with tiles.

•

There must be sufficient space around the

machine to facilitate use.

•

Proper lighting.

•

Do not set up the machine where there is

extreme temperature or humidity.

•

Protected from weather and wind.

•

Room with clean air.

•

Lower noise level than prescribed by general

regulations.

•

Explosive, corrosive and/or toxic materials

must not be stored in the same room.

•

From its location, the user must be able to see

the entire machine and the surrounding area.

No outside person may be on this surface and

no objects that may pose a risk may be there.

Service and repair of the machine must be

performed by a qualified service workshop. Any

electrical installation must be performed by a

qualified electrician.

Security

No modification or manipulation of the machine

may take place unless approved by the

manufacturer. The manufacturer disclaims all

responsibility for any injuries and accidents that

may occur as a result of such changes. It is strictly

forbidden to remove or tamper with the machine’s

safety devices. If this still happens, serious injury or

accident can occur.

Service, repair and spare parts

All maintenance and repairs must be carried out

by a qualified service workshop. Always unplug

the machine before performing any maintenance

or service. At an eventual repair, only original parts

may be used.

Storage

If the machine is to be stored unused for a long

time, disconnect it from the electrical outlet, make

sure that parts that can be damaged by dirt are

properly protected, and lubricate parts that can be

damaged if they dry.

Environmental protection/Scrapping

Recycle unwanted material instead of throwing it in

the household rubbish. All machines, accessories

and packaging materials must be sorted and left at

a recycling centre and disposed of in an

environmentally friendly manner.

Motor power (1-phase): 1 hk (0,75 kW)

Network connection:

230 V, 50 Hz

Maximum tyre width:

14”

Max tyre diameter:

41”

Internal clamping:

12”–24”

External clamping:

10”–21”

Maximum working

pressure:

10 bar (145 psi)

Maximum pressure:

2500 kg

Weight:

191 kg

Sound level:

< 75 dB

Dimensions (hxbxd):

1740x760x950 mm

Specifications

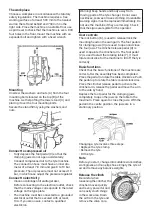

Transport

All transport of the machine must be done by a

hand truck. The forks must be placed according to

the figure.

Содержание 32836

Страница 1: ...Tyre changer U 2011 D ckmaskin U 2011 Item No 32836...

Страница 8: ...Varningsskyltarna...

Страница 9: ......

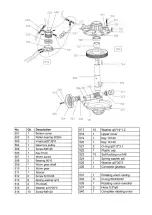

Страница 16: ...Exploded view...

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

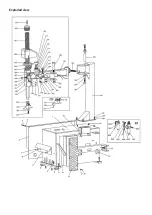

Страница 25: ...Electrical circuit diagram...

Страница 26: ...Pneumatic diagram...

Страница 28: ......

Страница 29: ......

Страница 30: ...Verktygsboden Erfilux AB K llb cksrydsgatan 1 SE 507 42 Bor s Verktygsboden Bor s Sweden 0120504 03...