15

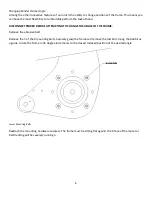

Belt Slippage and Wobbling

Belt slippage occurs when the tension is too loose or if there is some type of lubricant that has contaminated

the back of the abrasive belt.

Make sure oil or grease hasn’t contaminated the back of the belt. If so, replace belt.

Follow the retensioning proceedure. If this fails to retension the belt follow the steps below to reset the

preload on the main spring.

1.

Completely remove the belt.

2.

Remove bolt nuts from the tensioner assembly.

3.

Reinstall the first standard nut until it starts to compress the tension spring, continue a half turn.

4.

Reinstall the nylon lock nut against the first nut.

5.

While holding the nylon nut in place with one wrench, turn the first nut in the loosen direction to

tighten against the nylon nut.

If procedure fails to tension belt, replace tension spring.

Belt wobbling can occur if the upper or lower frame are not secured tightly or if the upper frame lock screws

are too loose. Belt wobbling can also occur if idler pulleys bearings are worn.

Check lock screws to make sure they are firmly tightened by hand.

Inspect bearings for worn or broken bearings.

Содержание DeBurr-It! 248-3

Страница 5: ...5 ...