P-K Storm

TM

Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: October 2, 2019

Released: October 2, 2019

Patterson-Kelley 2019

All Rights Reserved.

2691000099 P-K Storm Installation and Owners

Manual.docx

Page 46

Adjusting High Fire

Start the boiler and observe proper operating parameters for the system.

Access the “Manual Control Firing Rate”, as described above, and

increase the firing rate to 100%. Check combustion readings using the

combustion analyzer. If the combustion readings are not in accordance

with Section

, adjust as follows:

Required Tools

: Flat head screwdriver/no 2.5 allen wrench,

Combustion analyzer and water tube manometer.

1. Using a slotted screw driver, set the maximum restrictor (high fire

screw) on the outlet/shutter flange of the combination gas safety

shut off / control valve by turning clockwise or counterclockwise to

achieve the desired CO

2

or O

2

level. To increase the O

2

level,

adjust towards the “-“ symbol to decrease gas flow. To decrease

the O

2

level, adjust towards the “+” symbol to increase gas flow.

2. There will be a slight time delay between the adjustment and the

response of the CO

2

/O

2

measuring instrument. Clockwise rotation

decreases gas flow. Counterclockwise rotation increases gas flow.

Adjusting Low Fire

Required Tools

: 2.5 mm hex wrench and combustion analyzer.

Start the boiler and observe proper operating parameters for the system.

Set boiler to the

“

Manual Control Firing Rate

”

mode, as described above,

and decrease the firing rate to 1%. Once the boiler has reached low fire

operation, check combustion readings using the combustion analyzer. If

combustion readings are not in accordance

with the above table

, adjust

as follows:

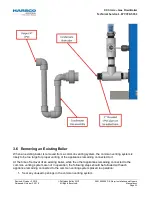

1. Using a 2 mm hex wrench, adjust the pressure regulator offset

adjustment (pictured above) to achieve the desired CO

2

/O

2

level.

To increase the O2 level, adjust towards the “-“ symbol to decrease

gas flow. To decrease the O2 level, adjust towards the “+”

symbol to increase gas flow.

2. Adjustments to the offset pressure regulator should not exceed ¼

turn at a time before allowing the readings to respond and stabilize.

Following all gas valve adjustments, check for proper light-off and verify correct fuel/air mix and

combustion quality throughout the entire firing rate (from low to high fire).

Checking Flame Signal

Tou

ch the “Info” button in the lower left corner of the NURO display to load the “Information” menu

which shows real-time read-only boiler values such as temperatures, relay states, etc. Scroll down the

“Information” menu to find the “Flame Signal” value. This value displays the strength of the combustion

flame (units = V) as measured by the ignition electrode/ionization probe. When the boiler is in standby,

prepurge, or postpurge the flame signal should read 0V. During main flame, a strong flame signal

should read between 8-25V.

Offset adjustment

NOTE: ALWAYS

adjust high fire combustion first!