www.parweld.com

www.parweld.com

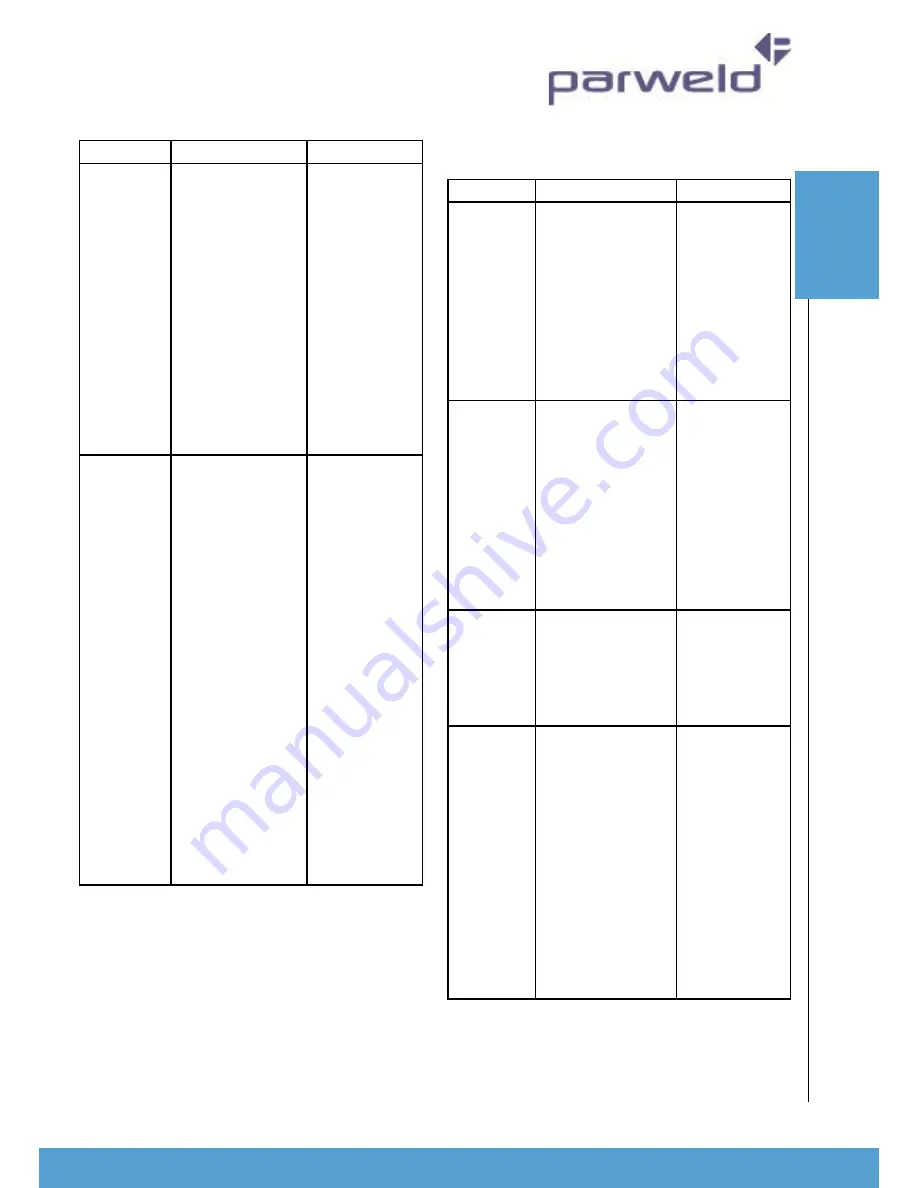

Description Possible Cause

Remedy

Welding arc

cannot be

established

(a) Work clamp is

not connected to

the work piece or

the work/torch

leads are not

connected to the

machine

(b) Torch lead is

disconnected

(c) Gas flow

incorrectly set,

cylinder empty or

the torch valve is

off

a) Connect the

work clamp to

the work piece

or connect the

work/torch

leads to the

right welding

terminals.

(b) Connect it to

the ‘.’ terminal.

(c) Select the

right flow

rate, change

cylinders or turn

torch valve on.

Arc start is

not smooth

(a) Tungsten

electrode is too

large for the

welding current .

(b) The wrong

electrode is being

used for the

welding job.

(c) Gas flow rate is

too high.

(d) Incorrect

shielding gas is

being used.

(e) Poor work

clamp connection

to work piece

(a) Select

the right size

electrode

(b) Select the

right electrode

type. Refer

to basic TIG

welding guide

(c) Select the

correct rate for

the welding job.

Refer to basic

TIG welding

guide

(d) Select the

right shielding

gas. Refer

to basic TIG

welding guide

(e) Improve

connection to

work piece

Power source problems

Description Possible cause

Remedy

The

welding arc

cannot be

established

(a) The primary

supply voltage has

not been switched

on

(b) The welding

power source switch

is switched off

(c) Loose

connections

internally

(a) Switch on

the primary

supply voltage

(b) Switch on

the welding

power source.

(c) Have a

qualified service

engineer repair

the connection

Maximum

output

welding

current

cannot be

achieved

with

nominal

mains

supply

voltage

Defective control

circuit

Have a qualified

service

engineer

inspect then

repair the

welder

Welding

current

reduces

when

welding

Poor work lead

connection to the

work piece

Ensure that

the work lead

has a reliable

electrical

connection to

the work piece

A total loss

of power,

pilot lamp

is off, no

output, the

fan is not

operating

(a) Failure of input

voltage

(b) Possible over

voltage

(c) Internal fault

with the machine

(a) Re-establish

mains supply

(b) Check

voltage and

if necessary

move machine

to alternative

supply

(c) Have a

qualified service

engineer

inspect then

repair the

welder

Faul

t

FI

n

DI

n

G

13

Содержание XTI-303 AC/DC

Страница 1: ...INSTRUCTION MANUAL...

Страница 2: ...Operator Manual ISSUE 2 XTI 303 AC DC...