www.parweld.com

10

Faul

t

FI

n

DI

n

G

3) Select AC output from (centre position)

4) Dial up the welding amperage required

5) Set the starting amperage at 50%

6) Set the down slope at 5 seconds

7) Set the post gas at around 5 seconds

8) Set the cleaning control to 0.

You are now ready to weld. The above settings are

a guide and you should adjust to suit the job you are

welding if you are unfamiliar with the machine try to

adjust only one parameter at a time so you become

familiar with its effect. With AC TIG welding the

cleaning control is used to adjust the balance between

heating and cleaning the work, For speed an longevity

of the Tungsten it is best to minimise the cleaning

effect but how low this can be adjusted will depend

upon the condition of the base material

7.0 Fault Finding

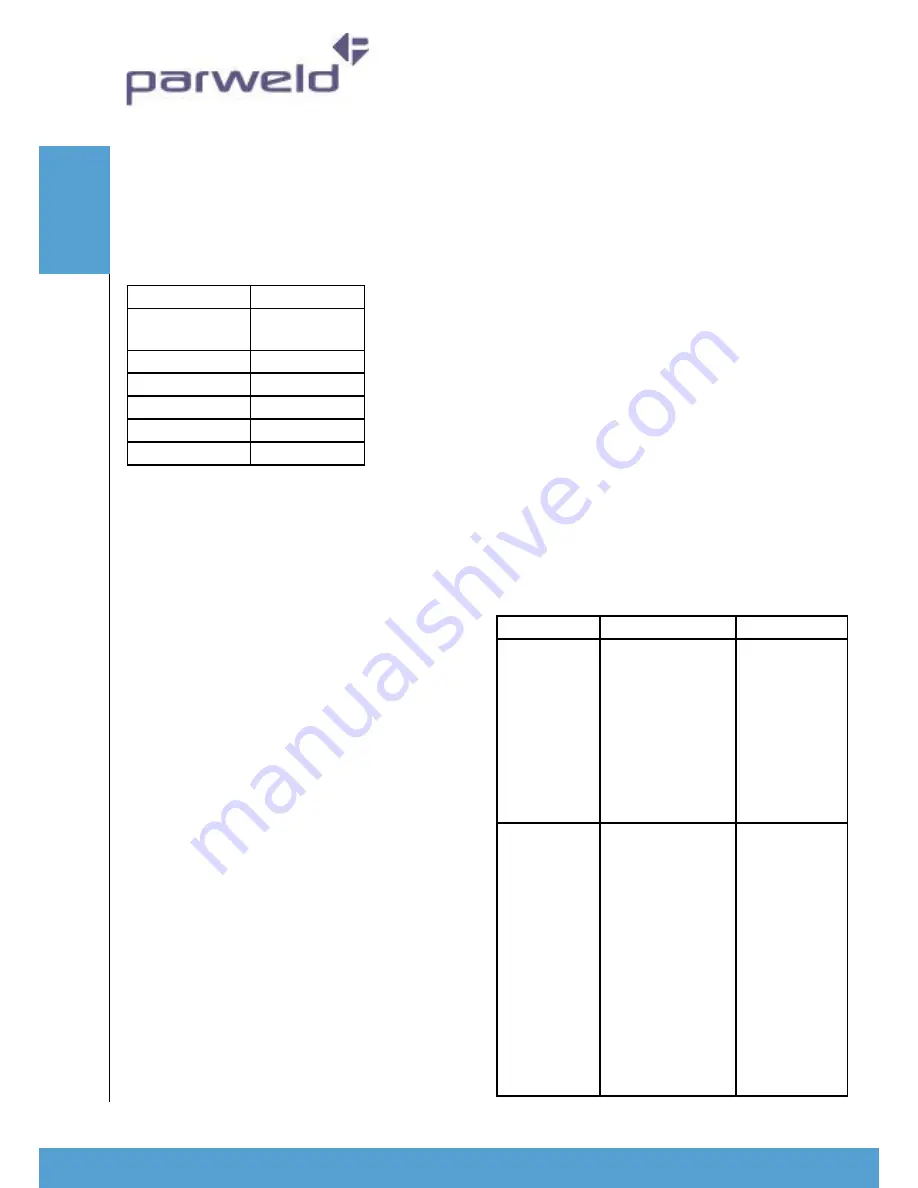

MMA welding problem

Description

Possible cause

Remedy

Gas pockets

or voids in

weld metal

(porosity)

(a) Electrodes are

damp

(b) Welding current

is too high.

(c) Surface

impurities such as

oil, grease, paint,

etc

(a) Dry

electrodes

before use

(b) Reduce

welding current

(c) Clean joint

before welding

Crack occur-

ring in weld

metal soon

after solidifi-

cation.

(a) Rigidity of joint.

(b) Insufficient

throat thickness.

(c) Cooling rate is

too high.

(a) Redesign

to relieve weld

joint of severe

stresses or use

crack resistance

electrodes.

(b) Travel

slightly slower

to allow greater

build up in

throat.

(c) Preheat

plate and cool

slowly.

The filler wire diameter specified is a guide only, other

diameter wires may be used according to the welding

application.

Shielding gas selection

Alloy

Shielding gas

Aluminium &

alloys

Pure Argon

Carbon steel

Pure Argon

Stainless steel

Pure Argon

Nickel alloy

Pure Argon

Copper

Pure Argon

Titanium

Pure Argon

Machine setup for TIG welding

DC TIG welding

Connect the torch as detailed previously

1) Select HF start (bottom position)

2) Set the process mode to 2T or 4T if you prefer a

latching trigger action. (Note in 4T position you must

press and release to start the process and press and

release again to stop the process)

3) Select DC output from (top position)

4) Dial up the welding amperage required

5) Set the starting amperage at 50%

6) Set the down slope at 5 seconds

7) Set the post gas at around 5 seconds

You are now ready to weld. The above settings are a

guide and you should adjust to suit the job you are

welding if you are unfamiliar with the machine try to

adjust only one parameter at a time so you become

familiar with its effect.

AC TIG welding

Connect the torch as detailed previously

1) Select HF start (bottom position)

2) Set the process mode to 2T or 4T if you prefer a

latching trigger action. (Note in 4T position you must

press and release to start the process and press and

release again to stop the process)

Содержание XTI-303 AC/DC

Страница 1: ...INSTRUCTION MANUAL...

Страница 2: ...Operator Manual ISSUE 2 XTI 303 AC DC...