2.

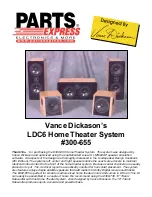

When positioning components try to keep lead lengths to a minimum. Note: The .10mH inductor used

on the L/Ctr/R crossovers should be mounted on its side to minimize the interaction between the two

coils on the board.

3.

Use RTV sealant or hot glue to mount the components to the board. We recommend using hot glue due to

its faster setup time. If you use RTV sealant, you may need to let it setup over night, before proceeding

with the assembly.

4.

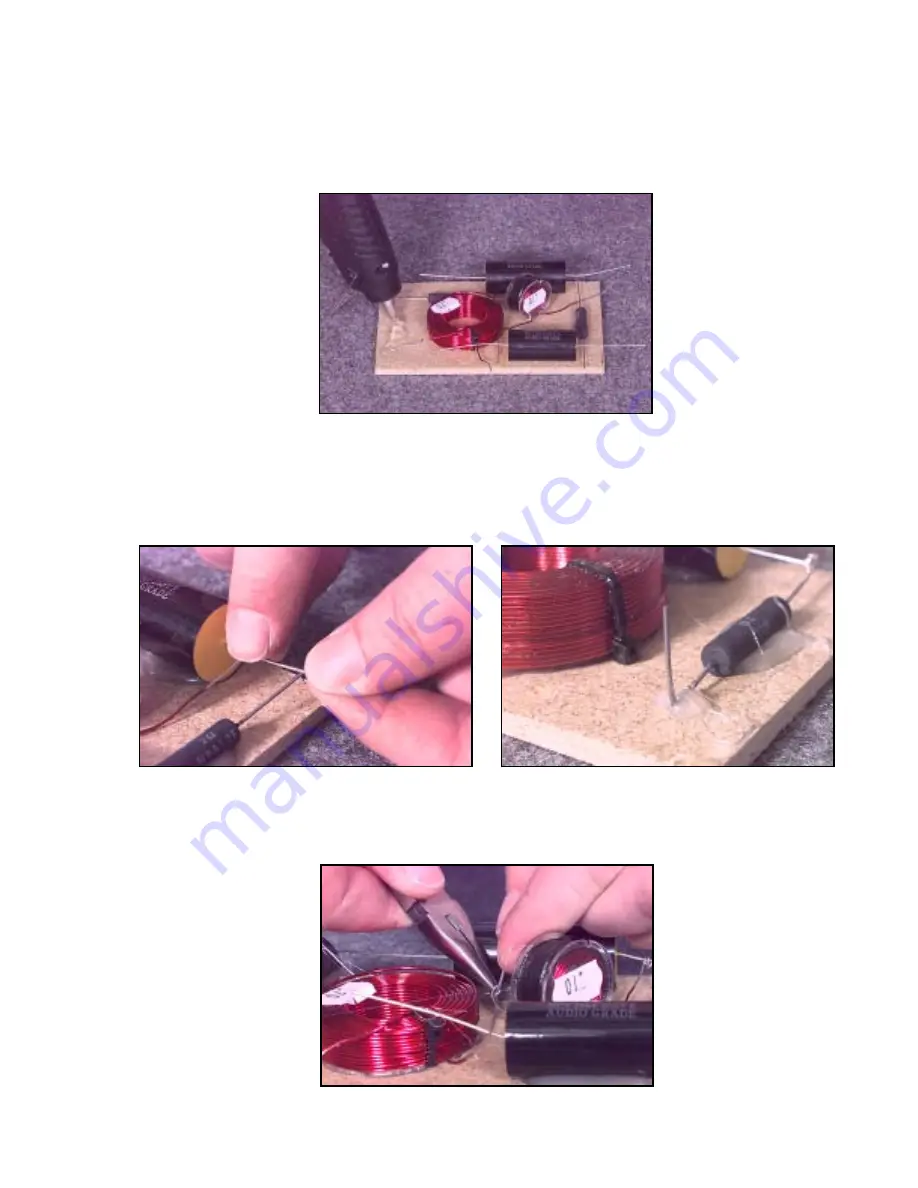

Connect all component leads as per their respective drawings. Note: Do not trim the component leads at

this time! The drawings show the locations where the input and output (driver) wires will connect (Fig.3,4).

At these locations, bend the component leads to create mounting posts for the input and output (driver)

wiring. This will make it much easier to terminate the wire, especially the ground connections. You can

secure the “mounting posts” to the board with hot glue or RTV to give the post more stability.

5.

Solder all component connections using silver or electronics grade (60/40) solder. A properly soldered

connection appears shiny and smooth. We recommend using a soldering iron with a wattage rating

between 20-30watts.

Page 4