6 GB/CY

Introduction / Safety of the fastener driving tool

Introduction

Pneumatic stapler PDT 40 C2

Introduction

We congratulate you on the purchase of your new

device. You have chosen a high quality product. The

operating instructions are part of the product. They

contain important information concerning safety,

use and disposal. Before using the product, famil-

iarise yourself with all of the operating instructions

and safety instructions. Use the product only as de-

scribed and for the specified applications. If you

pass the product on to anyone else, please ensure

that you also pass on all the documentation with it.

Intended use

The device is suitable for assembly and repair work.

Any other use or modification to the device shall be

considered as improper use and could give rise to

considerable dangers. We will not accept liability

for loss or damage arising from improper use. The

device is intended for private domestic use only.

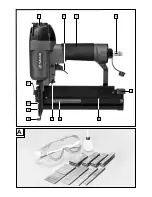

Features and fittings

1

Exhaust air aperture (can be rotated)

2

Trigger

3

Handle

4

Threaded nipple 6.35 mm (¼“)

5

Magazine

6

Fill level indicator

7

Knurled screw

8

Trigger lock

9

Mouth

10

Face plate

11

Face plate quick clamp lever

12

Magazine lever

Included items

1 Pneumatic stapler PDT 40 C2

1 Carrying case

1 Special compressed air oil

1 Threaded nipple 6.35 mm (¼“) (pre-assembled)

1 Package nails, 1000 pcs.

1 Package staples, 1000 pcs.

1 Protective glasses

1 Operating instructions

Technical data

Dimensions:

240 x 57 x 235 mm

(L x H x W)

Weight

(without fasteners):

1.255 kg

Trigger type:

Compressed air

Maximum permissible

pressure:

8 bar

Recommended pressure

range:

4 to 7 bar

Air consumption per

drive in process:

approx. 0.09 litre per

driving-in process

Recommended lubricant: Compressed air special oil

Loading capacity:

100 pcs.

Nail lengths:

15 mm, 20 mm

25 mm, 30 mm,

32 mm, 35 mm,

38 mm, 40 mm,

45 mm, 50 mm,

Staple lengths:

10–40 mm

Staple width:

5.7 mm

Recommended

Hose diameter:

∅ 9 mm

Compressed air quality: Cleaned, oil-misted

and condensate-free

Noise and vibration data:

Measured values for noise are determined in ac-

cordance with EN 12549:1999, EN ISO 4871.

The A-weighted sound pressure level of the device

is typically 114.3 dB(A). The sound power level of

the device is 125.6 dB(A). Uncertainty K = 2.5 dB.

These values are characteristic values referenced to

the device and do not reflect noise development at

the work location. Noise development at the work

location depends e.g. on the work environment, the

workpiece, the workpiece support and the number

of fastener driving processes.

Содержание PDT 40 C2

Страница 3: ...A 3 4 1 2 5 6 7 8 11 10 9 12...

Страница 4: ...B C D...

Страница 12: ...12...

Страница 20: ...20...

Страница 29: ...29 GR CY 30 30 30 30 31 32 33 33 33 33 34 34 35 35 35 36 36...

Страница 31: ...31 GR CY ISO 8662 11 1999 ah W 15 0m s2 0 29m s2 ISO 8662 11 1999...

Страница 32: ...32 GR CY 8bar 8...

Страница 33: ...33 GR CY 8 bar 1 4 2 1 12 2 01 02 5 5 02 5 01 5 3 5 8bar...

Страница 34: ...34 GR CY 2 8 2 0 5bar 0 5bar 2 9 2 9 9 2 7 7 7 1 5 10 11 8 10 11 1 5...

Страница 35: ...35 GR CY 5000 1 2 4 2 3 GR Tel 801 5000 019 0 03 EUR Min e mail kompernass lidl gr IAN 89568...

Страница 45: ......