www.parkermotion.com

Parker Hannifi n Corporation

Electromechanical Automation Division

4

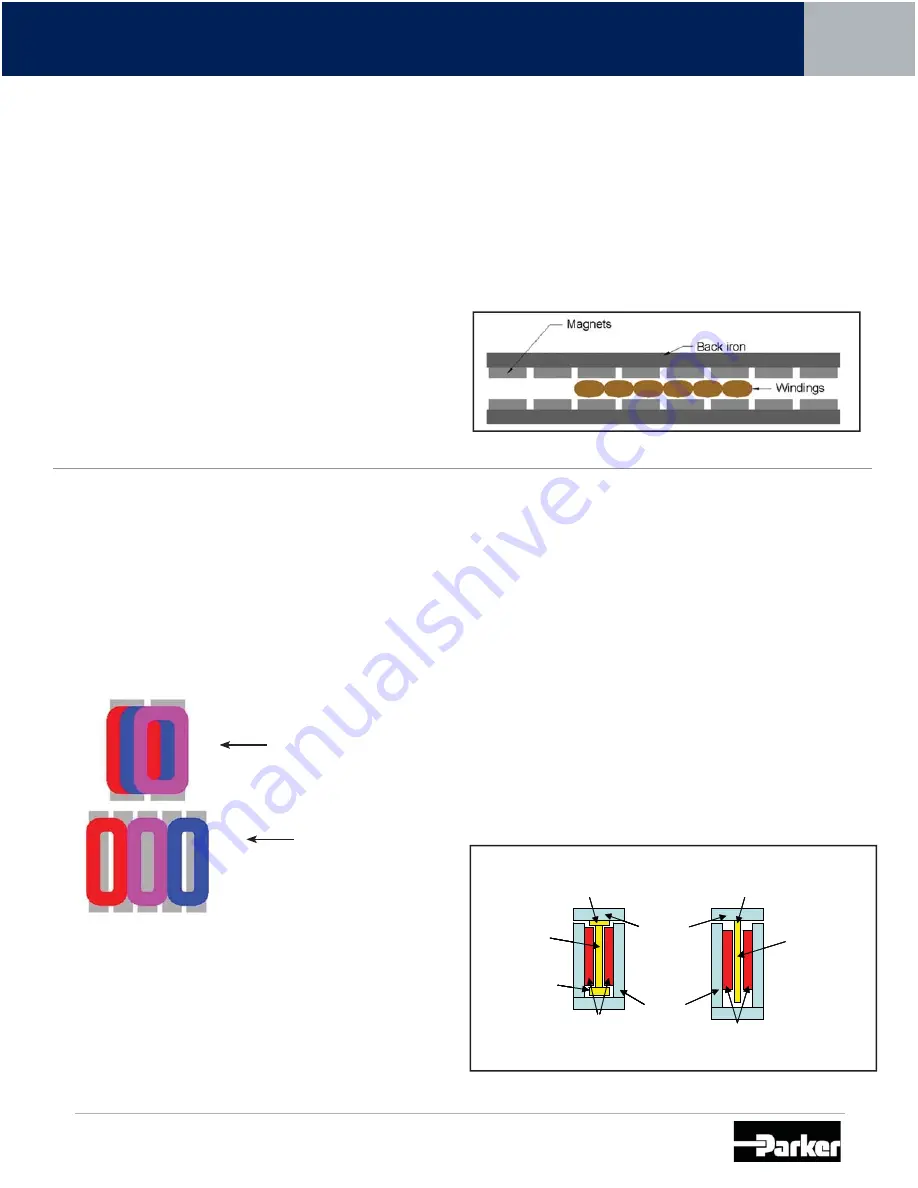

2.2 Ironless Motors

Ironless motors consist of a forcer which rides between dual magnet rails

(Fig. 8). They are also known as “aircore” or “U-channel” motors. The

forcer does not have any iron laminations in the coil – hence the name

ironless. Instead, the copper windings are encapsulated and located in

the air gap between the two rows of magnets. Because the motors are

ironless, there are no attractive forces or cogging forces between the

forcer and the magnet track.

In addition, the forcers have lower mass than their ironcore counterparts.

What results is a motor design that allows for extremely high accelerations

and overall dynamic performance. The ironless design has zero cogging

and the lack of attractive force allows for extended bearing life and, in

some applications, the ability to use smaller bearings.

While the high dynamic performance and zero cogging motion make the

ironless motors a powerful design, they are not as thermally effi cient

as their ironcore counterparts. A small contacting surface area and a

long thermal path from the winding base to the cooling plate makes the

full-load power of these motors low. In addition, the dual row of magnets

increases the overall cost of these motors in relation to the generated force

and stroke length.

Fig. 8: Ironless Linear Motor

Parker Trilogy’s patented I-beam shape and overlapping winding design

provides very high forces in a compact package. In addition, the design

is more thermally effi cient than tradition ironless motor designs.

By overlapping the windings (Fig. 9) instead of arranging them side-by-

side, Parker Trilogy is able to provide a motor with a very high power

density. The result is a package size considerably smaller than competitive

motors with similar force capabilities.

Overlapping windings for

shorter overall length

Non-overlapped windings

result in longer package length

Fig. 9: Overlapping Windings

Parker Trilogy creates the I-beam shape by fl aring out the end turns of

the motor at a 90-degree angle. The end turns of a linear motor coil do

not contribute to the horizontal force component of the motor. Instead

of producing force, the end turns simply produce heat. Parker’s I-beam

shaped design allows for better heat transfer between the motor coils

and the heat sink by increasing the contacting surface area between

components (Fig. 10). The combination of overlapped windings and the

I-Beam shape creates a more thermally effi cient motor than most

traditional ironless motors. As a result, the payload will experience

less thermal expansion due to heat from the motor. In high precision

applications, thermal expansion can adversely affect the overall system

accuracy. Parker Trilogy motors will help maintain system accuracy by

running at lower operating temperatures than our competitors. In addition,

there are added benefi ts of the I-beam shape by lowering the overall

profi le height and creating a stiffer mechanical structure.

What results is a compact motor design with high force and extraordinary

thermal characteristics.

Fig. 10: Parker Trilogy’s Patented I-Beam Design

Good surface area for

efficient heat transfer

Dual rows of magnets

Dual rows of magnets

Vacuum encapsulated

inronless coil with

I-beam shape

I-beam shaped coil for

lowerprofile, better

thermalefficiency and

higher structural stiffness

U-Shaped

magnet track

Non I-beam (T shaped)

coil with larger profile size,

less thermal efficiency

and less rigidity

acts as heat sink/

adapater plate

Small surface area for

poor heat transfer

Trilogy I-beam design

Competitive designs