K3.1.114o Manual NitroFlow Mobile

- 27 -

ATTENTION

The response time of the measurement is slow. Change the flow in small steps of a quarter

turn per step and wait until the display reading changes.

Do not close the flow control valve fully.

Adjusting the purity must preferably be done when the system is at normal operating

temperature after it has run for some time (1-2 hrs)

Adjusting the purity must be done while all sheet metal is mounted on the appliance

5. Once the desired purity has been reached, fasten the lock not on the spindle of the purity control valve

securely. Make sure you do not change the setting.

ATTENTION

Fastening the lock nut too tightly can have an influence on the purity of the output

7.4

Control of the outlet pressure

The outlet pressure of the generator can be controlled in two ways depending on whether is stored in a vessel or

not.

No nitrogen vessel installed:

Excess nitrogen will be vented; generator will run continuously. The

-function

must be off.

x

Close the ball valve V2 (refer to §3.3) at the outlet while the system is running.

x

Adjust the back pressure valve PCV (refer to §3.3) such that the outlet pressure on the default main

screen reads 8.0 bar(g)/116 psig at maximum. The lower the pressure is set the better for energy

consumption reasons and compressor life.

x

Open the ball valve V2 at the outlet.

Nitrogen vessel installed:

Excess nitrogen will be stored; generator will start and stop automatically. To set the

pressure switch (PSH) function in the software for this situation, proceed as follows:

x

Make sure the ball valve at the outlet (refer to §3.3) is open.

x

Close PCV completely (turn right) (refer to §3.3).

x

Set the switch-on pressure at maximum 7.0 bar(g). Switch-off pressure 8.0 bar(g). The lower the

pressure is set the better for the energy consumption reasons and compressor life.

x

Set the difference between the switch on and off pressure preferably not less than 1 bar. Smaller

differences will result in frequent switching which will shorten the life of the compressors.

NOTE

After the unit switches off due to reaching switch off pressure in the storage tank, the unit

cannot switch on within 5 minutes after the switch-off. The switch-on delay is there to prevent

too frequent start-up of the compressors that shorten the compressor life.

7.5 Stop

generator

1. Press the ON/OFF button to switch the unit OFF (in case it is operating).

2. Switch off the power switch before you perform maintenance.

3. Make sure the system is depressurised; check the internal pressure level in the maintenance menu

(screen 3/5)

4. When you restart afterwards there is a 3 minutes delay before it starts again.

Содержание NitroFlow Basic Series

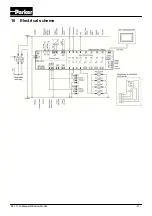

Страница 32: ...K3 1 114o Manual NitroFlow Mobile 31 10 Electrical scheme...

Страница 33: ...K3 1 114o Manual NitroFlow Mobile 32 11 Declaration of Conformity...

Страница 34: ...NOTES...

Страница 35: ......