Identify and eliminate faults

HDK-MT350_EN_04

43

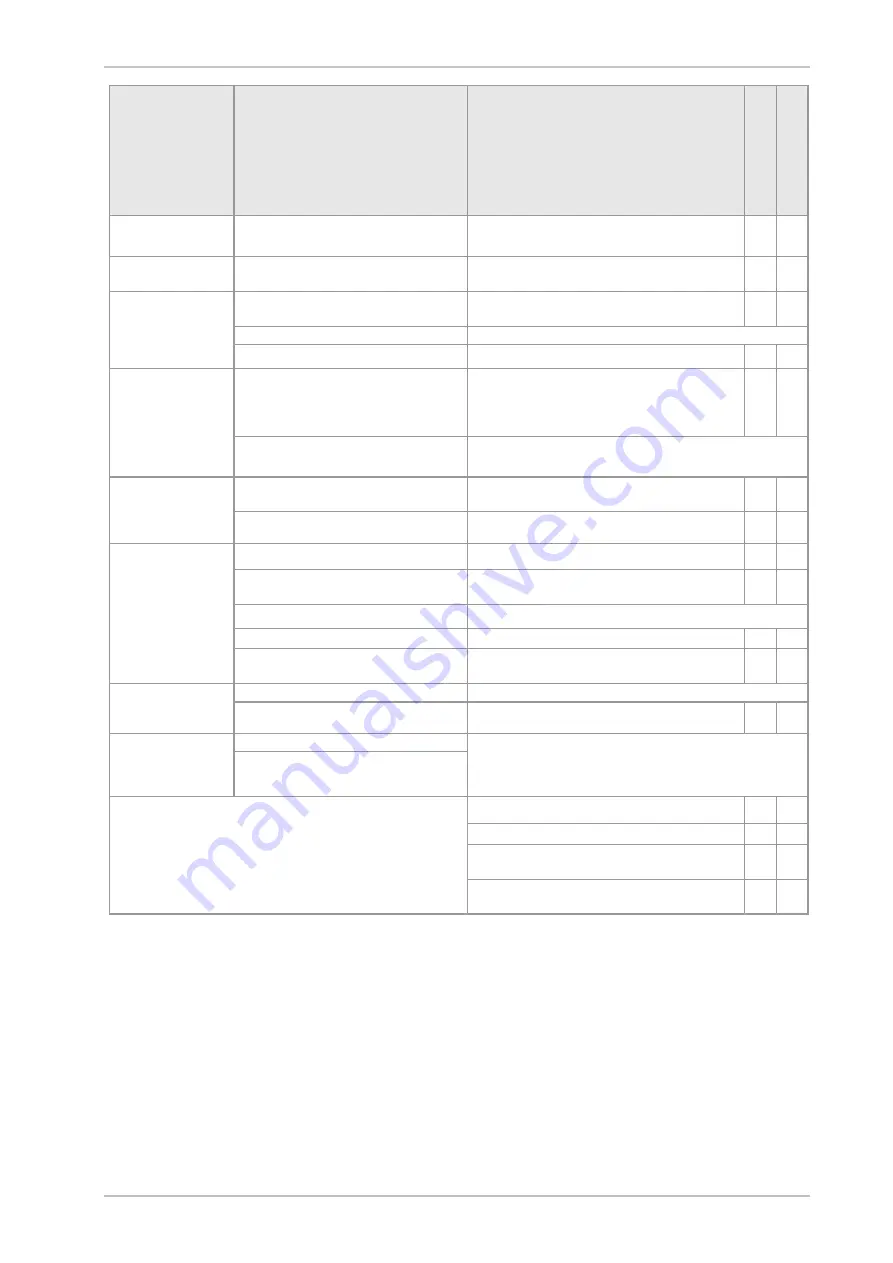

Fault

Possible cause

Remedy

S

p

eci

al

ised

p

e

rs

o

n

n

e

l

S

er

vi

ce t

ech

n

ici

an

Insufficient regeneration gas

Check function of valve Y3/Y4 and muffler;

replace filter element of muffler, if necessary.

Pressure in vessel

too low

Excessive differential pressure at

upstream filter

Check differential pressure at the upstream

filter; replace filter element, if necessary.

Backpressure

during regeneration

too high

Muffler contaminated

Check muffler for contamination; clean or

replace, if necessary.

Valve Y3/Y4 does not open properly

see *

Solid filter soiled.

Clean or replace the solid filter.

No pressure build-

up

Compressed pressure system

upstream from the dryer is not

pressurised

Check whether the compressed pressure

system upstream from the dryer is

pressurised. Eliminate any faults in the

compressed air system.

Valve Y1/Y2 or Y5 does not open

properly.

see *

Excessive

compressed air

consumption

Condensate trap (optional) at the

upstream filter is not working properly

Check condensate trap (optional); clean or

replace, if necessary.

Regeneration air setting too high.

Have adjusted.

Dryer fails to switch

over

Compressor is switched off

Check compressor synchronisation.

Power supply interrupted, cable

broken.

Reconnect the unit to the power supply.

Valve Y1/Y2 does not open properly

see *

Error in control programme

Restart programme.

Control board defective

Check fuses (switchbox, supply line); replace

board, if necessary.

No expansion in

chamber

Valve Y3/Y4 does not open properly

see *

Operating pressure too low.

Increase the operating pressure.

Dryer is

continuously bled

Valve Y3/Y4 does not close properly

see *

Valve Y1/Y2 does not close properly

*

Valve fails to open or close properly

Check supply voltage.

Check whether coil is properly mounted.

Inspect valve for contamination; clean or

replace, if necessary.

Check voltage at cables, contacts and coils;

replace defective parts as necessary.

Содержание HDK-MT 10-100

Страница 1: ...High Pressure Dryer HDK MT 4 100 70 350 Operating Instructions Revision 04 2014 EN ...

Страница 6: ...Manufacturer s details 6 HDK MT350_EN_04 General information Manufacturer s details Name and address ...

Страница 52: ...Logic control diagram 52 HDK MT350_EN_04 Logic control diagram Adsorption in B1 and regeneration in B2 ...

Страница 53: ...Annex with technical documentation HDK MT350_EN_04 53 Regeneration in B1 and adsorption in B2 ...