BA_PH_335-20_EN_07-22.docx

29

10

Machine Operation

All adjustment and operation work is only permitted when the cutter block is stopped!

10.1

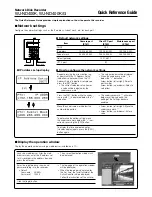

Electrical Chip Removal Adjustment

Figure 16:

Chip removal

The chip removal thickness is set with the keys (

U

) and (

D

).

•

Pressing button (

D

) lowers the infeed table

The chip thickness increases.

•

Pressing button (

U

) raises the infeed table.

The chip thickness decreases.

10.2

Hollow and Pointed Joint Adjustment

With the adjusting screw (

S

) under the outfeed table, the outfeed table can be inclined to the infeed table so

that a hollow or a pointed joint is obtained.

Figure 17: Hollow / pointed joint adjustment

Clockwise

↻

- upwards -

> Pointed joint<

Counterclockwise

↺

- downwards -

< Hollow joint >

The analogue scale (

A

) enables the ex-

act setting of the outfeed table. The

current table status is shown on the

digital indicator.

Important: Hollow and pointed joint adjustment only when the control unit is switched on.

10.2.1

Calibrate Hollow and Pointed Joint on the Digital Indicator

If the adjusting screw (

S

) for the hollow and pointed joint adjustment has been adjusted whilst the digital dis-

play was switched off, the position will no longer correspond to the analogue scale when the digital indicator is

switched on.

To synchronize the analogue and digital display, proceed as follows:

•

Switch off the digital unit via the main switch (

H

).

•

Use the adjusting screw (

S

) to reset the pointer to the original position on the outfeed table.

•

Switch on the digital unit again

The digital display has taken over the position of the outfeed table.

Furthermore, the angle for the hollow and pointed joint of the digital display can be calibrated to the zero

point. The procedure for this is described in detail in section

U

D

II

I

0

I

II

Hohl- und Spitzfuge

Einstellung

Diese Einstellung nur bei eingeschalteter

Steuerung vornehmen!

S

A