PAT1M / PAT1.5M OPERATION MANUAL

PAT1M/PAT1.5M: PA22222A01_03

Page: 25 of 36

Dec., 2007

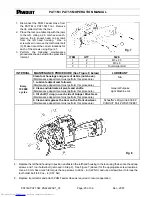

1. Disconnect the PHM Feeder Hose from

the PAT1M or PAT1.5M Tool. Remove

the tip collector from the tool.

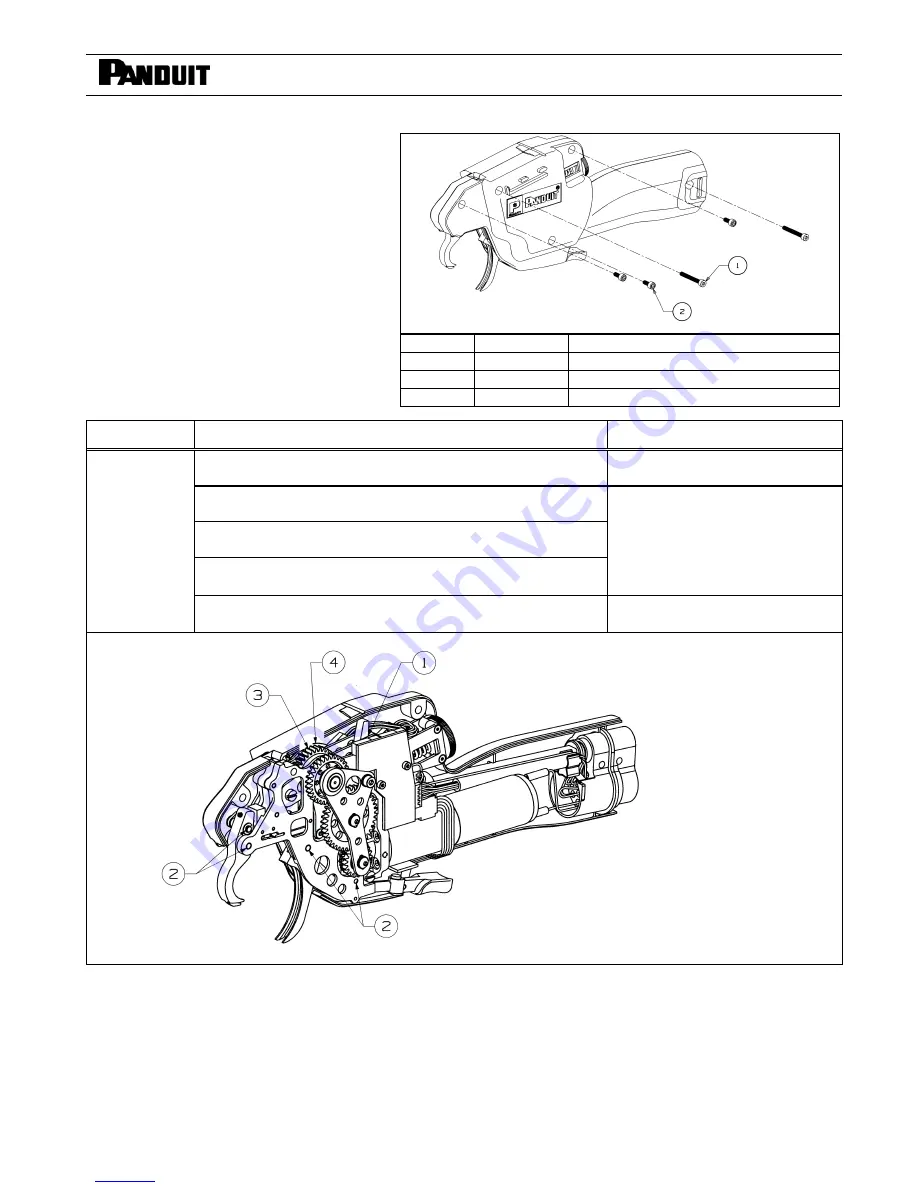

2. Place the tool on a table top with the jaws

to the left. Using a 2.5 mm hex wrench,

remove the 4 socket head cap screws

from the left hand housing. Use a

screwdriver to remove the tool holder bolt

(3). Make note of the correct locations for

each of the screws using Figure 7.

ITEM QTY

SIZE

1

2

M3 x 25

2

2

M3 x 8

3. Perform the following maintenance

procedures shown below at the prescribed

interval:

3

1

Tool Holder Bolt

INTERVAL

MAINTENANCE PROCEDURE (See Figure 8 below)

LUBRICANT

Clean tool housings and gears of debris (not shown).

(Maintenance department must perform this procedure.)

N/A

1. Lubricate detent cam follower.

(Maintenance department must perform this procedure.)

2. Clean and lubricate all pivots and shafts.

(Maintenance department must perform this procedure.)

3. Oil shaft (1 drop) on each side of Gripper Drive Gear.

(Maintenance department must perform this procedure.)

General Purpose

Light Machine Oil

Every

100 000

cycles

4. Clean and regrease the Cam on the Front Jaw Gear.

(Maintenance department must perform this procedure.)

Schaeffer's Moly Ultra 800 EP

PANDUIT

Part # WS23132B01

4. Replace the left hand housing in position and fasten the left hand housing to the tool using the 4 socket head cap

screws and 1 tool holder bolt (removed in Step 2). See Figure 7 (above) for the appropriate screw locations.

Use a 2.5 mm hex wrench to torque the cap screws to 60 oz - in (0,42 Nm) and use a screwdriver to torque the

tool holder bolt to 80 oz - in (0,57 Nm).

5. Replace tip collector and attach PHM Feeder Hose as required to resume operation.

Fig. 7

Fig. 8

electronic components distributor