9

FEEL SAFE TO USE IT.

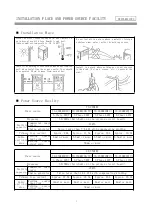

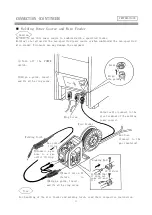

Welding power source

PREPARATIONS

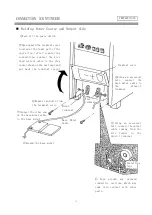

Crater Current Control

When

“

CRATER ON

”

is selected with

the crater selector switch, you can

control a crater welding current

value.

Crater Voltage Control

When

“

CRATER ON

”

is selected with the crater selector

switch, you can control a crater welding voltage. Note)

When SIMPLE UNIFIED is selected (refer to pages 25 and

44), this serves as a crater voltage fine control.

A unified crater voltage may not be an optimum

condition, depending on a welding posture, wire brand,

and length of an extension cable. If this is the case,

the crater voltage can be finely adjusted "lower" by

turning this control to the left, and "higher" by

turning to the right.

Gas Supply Switch

Warn. Indicator Lamp

Power Indicator Lamp

Prior to welding, use this

switch to adjust a gas flow

rate in advance. Set it to

the

“

CHECK

”

side.

(Refer to page 15)

When a warn. occurs, this

lamp goes on. It informs

you of an warn inside the

welding

power

source.

(Refer to page 34)

This

lamp

indicates

a

power-on/-off state.

Turning on the POWER switch

Illuminates a green lamp.