21

direction.

Verification of proper rotation is done by observing suction and discharge pressures when the compressor is

operating. A decrease in discharge pressure and an increase in suction pressure indicate reverse rotation. In

order to correct this situation, disconnect the power and switch any two power leads at the unit contactor.

NEVER switch leads directly at the compressor.

Internal wiring of the compressor is consistent with the direction of rotation. As a result, once the correct

phasing is determined for a specific system or installation, connecting properly phased leads to the same

terminals should maintain proper rotation direction.

A phase monitor can be applied to ensure correct rotation when power is initiated. Each compressor is labeled

with the appropriate sequence. As showed in wiring diagram, the line phases R (L1), S (L2) and T (L3) should

be connected to terminals U, V and W, respectively.

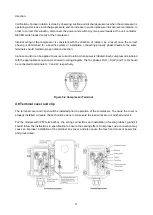

Figure 5-4 Compressor Terminal

4.9 Terminal cover and clip

The terminal cover and clip should be installed prior to operation of the compressor. To ensure the cover is

properly installed, a double check should be done to make sure the lead wires are not pinched under it.

For the models with IP67 terminal box, the wiring connections and installation of sealing rubber, gland kit

should follow the instructions in specification to ensure the sealing effect. An improper wire connection may

cause an improper installation of the terminal box cover, and also cause the touch and cross of power line

and ground lead.