9

Palmgren Operating Manual & Parts List

84315

OPERATION (CONTINUED)

When You Can Cut and When You Must Scrape

There are two different approaches:

•

One approach is toward a circumference of the workpiece (for

example turning down the outer surface of a cylinder or the

inner wall of a hollow round box). In this approach, the surface

being turned travels under the chisel edge like an endless belt.

•

The second approach is toward the diameter of a workpiece (as

when turning the face of a faceplate turning, or the side of a

large shoulder on a spindle turning). In this approach, the sur-

face being turned rotates like a disc under the chisel edge.

•

Sometimes the optimum approach will be a combination of

both methods.

Either a cutting or scraping action can be used when the approach

is toward a circumference – the shaving is removed like a peeling

from a potato. Scraping can only be used when the approach is

toward a diameter. The reason is obvious when you consider that

faceplate turning practically always requires removal of wood

across the grain. Wood does not peel easily across the grain and

attempts to use any inappropriate cutting methods will likely

result in damage to the workpiece. There is also danger that the

tool could be pulled from the hands of the operator.

In general, a cutting action is used for the majority of spindle turn-

ing operations while faceplate turning is usually accomplished by

the scraping method. When a combination approach is to be used,

the operator will have to judge, by the feel of the work, when to

stop cutting and start scraping.

Never

try to cut when it becomes

difficult to hold the chisel against the roughness of the wood grain.

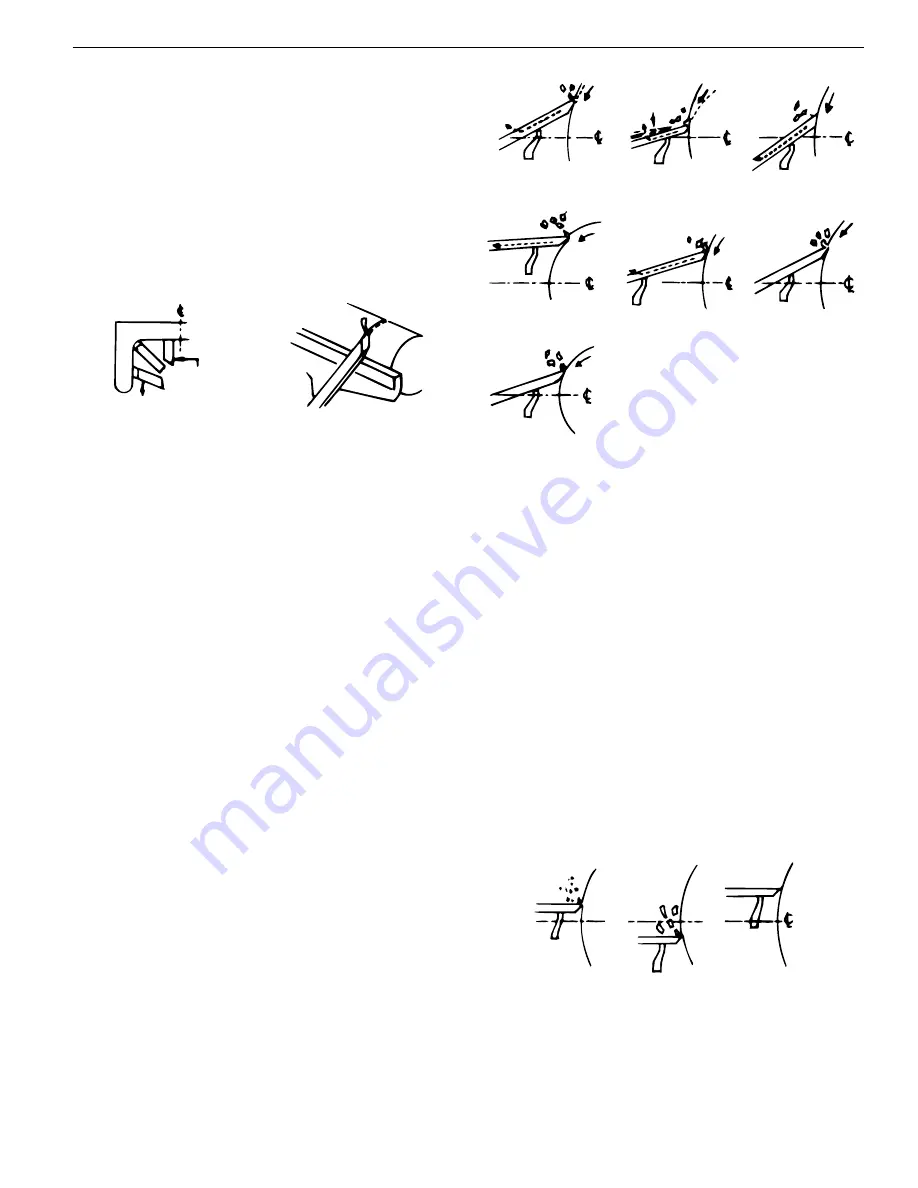

How to Position Tool Rest for Circumference Cutting

When cutting, the object is to pierce the outer skin of wood to a

certain desired depth and then to hold the chisel steady with the

bevel edge parallel to the work circumference so that it will peel

off a shaving at this desired depth.

•

The only sure method of holding the chisel steady is to rest the

bevel against the work (Figure 25A). When the tool rest is at the

proper height, the chisel can be held with the bevel pressed

against the work, and the tool rest will act as a fulcrum to sup-

port the chisel against the downward force of the revolving

work.

•

If the rest is placed too low, so that the chisel is held with the

bevel out from the work (Figure 25B), the cutting edge will con-

tinue to dig deeper into the work. It will dig in until the “bite”

becomes so deep that your hands have difficulty holding the

chisel – then the improperly supported chisel will begin to

bounce or chatter against the workpiece.

•

If the rest is placed too low, the chisel must be held extremely

high to position the bevel against the work (Figure 25C). Then

the rest loses most of its value as a fulcrum and the downward

force of the revolving workpiece tends to kick the chisel back

out of your hands.

•

If the rest is placed too high (Figure 25D) and the chisel is cor-

rectly positioned for cutting, it strikes the workpiece near the

top where the direction of force exerted by the workpiece is

nearly horizontal – and kickback will again result.

•

If the rest is placed too far out from the work surface (Figure

25E), then, when correctly held, the chisel is again too high on

the work. Also, you have less leverage on your side of the tool

rest and it is even more difficult to hold the chisel. With large

diameter work (Figure 25F), the tool rest can be above the

workpiece centerline, and somewhat out from the work sur-

face. With small diameter work (Figure 25G), the rest should be

closer to the work surface. As work grows smaller, the rest

should be repositioned.

How to Position Tool Rest for Circumference Scraping

In scraping operations, the tool rest position is not as critical as it is

for cutting operations.

•

The chisel generally is held horizontally, though it can be held

at an angle to reach into tight places. Considering that the wire

edge of the chisel does the scraping, Figures 26B and 26C show

the results of too low or too high a position for the rest.

•

Figure 26A shows the chisel action with the rest correctly

positioned.

How to Position Chisel and Rest for Diameter Scraping

When scraping on the diameter, that portion of surface to the right

of center is moving upward (Figure 27A). If a chisel is placed in this

area, it will simply be carried up off the rest and out of your hands.

•

All diameter approach operations must be done at the left of

center.

Diameter

Approach

Circumference

Approach

Figure 24

Steady

Thrust

Against

Hands

Chatter

Kickback

Kickback

Bevel

Against

Work

Chisel Rest

Too High

On Work

Handle

Kicked Up

Large

Diameter

Small

Diameter

No Support

For

Bevel

Point

Digging In

Chisel Cutting Properly

Rest Too Distant - Chisel Too High

Point Too Far From Rest

Rest Too Low

Chisel Too Horizontal

Rest

Too Low

Chisel

Too High

Figure 25

Fig. 25A

Fig. 25B

Fig. 25C

Fig. 25D

Fig. 25G

Fig. 25E

Fig. 25F

No Stock

Removed

Edge

Digging

In

Correct

Figure 26

Fig. 26A

Fig. 26B

Fig. 26C