RECOMMENDED ACCESSORIES

25

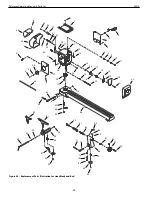

Palmgren Operating Manual & Parts List

84315

R

RE

EP

PL

LA

AC

CE

EM

ME

EN

NT

T P

PA

AR

RT

TS

S L

LIIS

ST

T F

FO

OR

R H

HE

EA

AD

DS

ST

TO

OC

CK

K A

AN

ND

D B

BE

ED

D

Ref.

No. Description

Part No.

Qty.

1

5-0.8 x 10mm Flat Head Screw

07458.00

4

2

Top Cover

18063.00

1

3

Line Cord

00090.00

1

4

Strain Relief

01680.00

1

5

Side Cover, Right

18064.00

1

6

5-0.8 x 10mm Pan Head Screw

*

15

7

Spacer

18065.00

1

8

3BMI-19 Retaining Ring

18066.00

1

9

607zz Ball Bearing

18067.00

1

10

Pulley

18068.00

1

11

6-1.0 x 45mm Socket Head Bolt

01862.00

1

12

6-1.0 x 16mm Socket Head Bolt

*

6

13

5-0.8 x 6mm Set Screw

*

2

14

Idler Pulley

18069.00

1

15

3AMI-14 Retaining Ring

05989.00

2

16

Sleeve

18070.00

1

17

Stationary Switch

18071.00

1

18

Rotating Switch

18072.00

1

19

Fan Drive Pulley

18073.00

1

20

Fan Belt

18074.00

1

21

6-1.0 x 75mm Socket Head Bolt

18075.00

1

22

Front Cover

18076.00

1

23

Pin

18077.00

1

24

Sleeve

18078.00

2

25

8-1.25 x 165mm Socket Head Bolt

18079.00

2

26

Plate

18080.00

1

27

Side Cover, Left

18081.00

1

28

Headstock Body

18082.09

1

29

5mm Flat Washer

*

3

30

Knob

18083.00

1

31

Switch with Key

16080.00

1

32

Pin with Chain

18084.00

1

33

Rear Cover

18085.00

1

34

Upper Rear Cover

18086.00

1

35

5-0.8 x 12mm Socket Head Bolt

*

1

36

Spacer

18087.00

1

37

Index Pin Lever

18088.00

1

38

5-0.8 x 30mm Socket Head Bolt

*

2

39

Block

18089.00

1

Ref.

No. Description

Part No.

Qty.

40

Stud

18090.00

2

41

Spring

18091.00

1

42

Index Pin

18092.00

1

43

Center Removal Rod

18093.00

1

44

Handle

18094.00

1

45

Eccentric Shaft

18095.00

1

46

Lathe Bed

18096.09

1

47

Threaded Rod

18097.00

2

48

Plate

18098.00

1

49

10-1.5mm Hex Nut

*

2

50

6

″

Tool Rest

18099.09

1

51

12

″

Tool Rest

18100.09

1

52

Locking Bar

18101.00

1

53

3AMI-12 Retaining Ring

00519.00

2

54

Bushing

18102.00

1

55

Tool Rest Holder

18103.09

1

56

12-1.75 x 30mm Eye Bolt

06974.00

1

57

Locking Handle

18104.00

1

58

Clamping Plate

06976.00

2

59

12-1.75mm Hex Nut

*

2

60

#2MT Bearing Center

20247.00

1

61

Quill

18105.00

1

62

Lead Screw

18106.00

1

63

Locking Handle

18107.00

1

64

5 x 16mm Spring Pin

00523.00

1

65

6-1.0 x 8mm Set Screw

01043.00

1

66

Tailstock

18108.09

1

67

Bushing

18109.00

1

68

8-1.25 x 10mm Set Screw

*

1

69

Handwheel

18110.00

1

70

Handle

18111.00

1

71

Locking Handle

18112.00

1

72

Cam Shaft

18113.00

1

73

Steel Ball

18114.00

1

74

Spring

18115.00

1

75

12-1.75 x 50mm Eye Bolt

06988.00

1

76

Screw

18117.00

1

77

Sleeve

18118.00

1

∆

Lathe Stand

70104

∆

Copy Crafter

84902

* Standard hardware item available locally.

∆

Not Shown