18

Palmgren Operating Manual & Parts List

84315

OPERATION (CONTINUED)

•

Smaller balls can be mounted as faceplates on the small face-

plate or screw center.

•

Lines drawn to indicate the center and ends of the ball shape

are helpful in plotting the curve.

•

A template should always be used for accurate visual observa-

tion of the work progress.

If the ball is mounted as a faceplate turning, almost the entire sur-

face can be turned before it becomes necessary to rechuck it.

•

Rechucking can be be accomplished in a deep cup chuck which

will hold the finished portion of the ball in a tight press fit.

Another method of rechucking is to use a shallow cup chuck

which will not support the ball alone, but must be used in conjunc-

tion with the tail stock.

•

When using the shallow chuck, a wood block is fitted to the tail

stock so that the ball can revolve upon it. This block should be

lubricated with beeswax or grease.

•

In using the shallow chuck method, the ball is constantly shift-

ed – never more than

1

/

8

turn – and always in a definite pattern.

•

Since turning between centers makes the work a perfect

sphere across the grain, the ball must be mounted in the chuck

so that the first scraping cuts will round it up in the opposite

direction.

TURNED BOXES

Turned boxes involve deep recessing together with a special sys-

tem of working the lid and body of the box together as one unit.

•

The inside of the lid is turned first.

•

Next, the inside of the body is turned. A careful check must be

made when turning the lip of the body portion so that the lid

will be a tight press fit.

•

The lid is then pressed onto the body and the outer circumfer-

ence and face of the lid, together with the outer circumference

of the body, are turned all at one time. This insures accurate

matching of the two pieces.

•

After the work is complete, the tight fit of the lid can be

relieved by sanding the lip of the body.

SEGMENTED TURNINGS

Segmented bowls and boxes are exceptionally attractive – and this

method of preparing wood stock is more economical than the use

of a large piece of stock. For some types of work, segmenting is the

only practical method because a block (if obtainable) would be so

large that it would be very likely to warp.

•

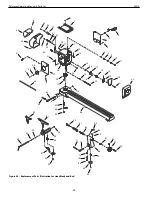

The bowl illustrated in Figure 66 requires 12 segment pieces for

the sides. Bowls can also be worked with 6 or 8 pieces.

•

To make the 12-piece bowl, a board about

1

/

8

x 3 x 30

″

is cut

into pieces about 2

1

/

2

″

long, the saw blade being tilted 15° and

the board being turned alternately face up and face down to

make the successive cuts.

•

These 12 pieces are glued together and clamped by wrapping

the assembly with wire (or equivalent).

•

When dry, the rim thus formed is glued to a temporary circular

backing which is mounted on a large faceplate.

•

A

3

/

4

″

deep recess of the largest possible diameter is turned in

the open end of the rim.

•

The rim is removed from the lathe and stock for the bottom is

mounted in its place on a second faceplate. This is turned to

size – and a rim about

1

/

8

″

deep is turned to exactly fit the

recess prepared in the rim.

•

The rim is then fitted over the bottom and glued, making a

drum shape with a faceplate at each end.

•

This drum is cut completely in two at a point about

3

/

4

″

above

the bottom – completing the cut with a hand saw.

•

Both parts of the cut surface are faced off square and smooth –

then reglued together, breaking the joints exactly half and half.

The cutting and regluing process is repeated with a section

about 1

1

/

4

″

wide.

•

After this, the temporary backing block is cut off, leaving the

bowl as shown in the final illustration. From this point on, the

work is simply a matter of turning down the bowl to any

desired shape.

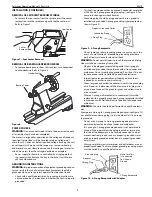

Figure 67

Figure 69

Figure 68

Screw Center

Backing Block

Lids

Body

Lid

Face Plate

B.B.

Tailstock

Center

Woodblock

Shallow Bearing Center

Deep Cup Chuck

Figure 71

Figure 70