4

A

AS

SS

SE

EM

MB

BL

LY

Y

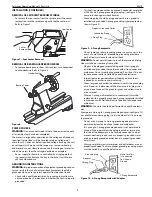

Refer to Figures 2 - 6.

CAUTION:

Do not attempt assembly if parts are missing. Use this

manual to order replacement parts.

•

Remove all components from the shipping carton and verify

against the parts list on page 2. Clean each component and

remove shipping preservatives (coatings) as required.

•

After selecting an appropriate bench, table, or lathe stand, set

the bed towards the front and the left side.

•

Turn bed on its side with the bottom of the bed facing towards

you and with the headstock end of the bed on the left side.

•

Place headstock assembly on its side near the left end of the

bed. Install the threaded rods into the headstock.

•

Move headstock into the bed so that the hub on the bottom of

the headstock seats into the hole in the bed. Place plate over

the eccentric shaft onto the threaded rods and secure in posi-

tion with hex nuts.

•

Place lathe upright. Install locking handle into eccentric shaft.

Secure alignment pin chain to bed with screw. Position head-

stock so that spindle faces toward opposite end of bed. Insert

alignment pin through headstock into the bed. Install head-

stock in position by pulling locking handle forward. Secure

speed control knob using washer and screw.

•

Slide the tool rest base assembly onto the bed. Make sure

clamping plate is oriented with slot in bed. Secure the position

with locking handle. Place 12

″

or 6

″

tool rest into base and

secure in position.

•

Slide tail stock assembly onto the bed in the same manner as

the tool rest base. Install locking handle and secure in position.

•

When the wood lathe is ready for use, it should appear as it

does in Figure 6.

•

Examine the line cord to make sure that the plug is in good

condition and that the insulation has not been damaged dur-

ing transit.

IIN

NS

ST

TA

AL

LL

LA

AT

TIIO

ON

N

Refer to Figures 7 - 12.

MOUNTING LATHE TO BENCH

•

Position the lathe assembly on top of a suitable stand or bench.

The headstock end should be close enough to a side edge so

that outboard operations can be performed without difficulty.

•

Verify that the bed is resting flat on the bench top. Mark the

mounting hole locations using the holes in the bed as a guide.

Move the lathe and drill four

3

/

8

″

holes through the bench top.

Place the lathe back in position and feed four

5

/

16

x 2

″

carriage

bolts through the holes in the bed. Secure from underneath

with flat washers, lock washers, and hex nuts (not supplied).

STABILITY OF WOOD LATHE

If there is any tendency for the lathe to tip over or move during

certain cutting operations, such as cutting extremely heavy pieces

or long, out-of-round objects, the lathe should be bolted down.

LOCATION OF WOOD LATHE

The lathe should be positioned so that neither the operator nor a

casual observer is forced to stand in line with the spinning chuck.

INSTALLATION OF CENTERS

The spur center and the bearing center have Morse taper #2 to

match the spindle and tail stock bores. To install the centers, slide

them into the bores with a firm, swift movement. They will be fur-

ther secured when a workpiece is squeezed between the centers.

Palmgren Operating Manual & Parts List

84315

Figure 2 – Install Threaded Rods

Plate

Eccentric Shaft

Threaded Rod

Headstock

Bottom

Figure 3 – Mount Headstock

Figure 4 – Secure Headstock

Figure 5 – Tool Rest

Figure 6 – Completed Assembly

Bearing

Center

Locking

Handle

Locking Handle

Spur Center

Tool Rest

Bed

Headstock

Locking

Handles

Clamping Plate

Tailstock

Speed

Control

Knob

Alignment Pin

Locking Handle

Screw