ILSL 33/44 Owner‘s Manual

Rev.1.1

20

6.3

Checking and Changing the Oil

Check the quality of the hydraulic fluid, the fluid should be free of contaminants such as debris, sludge,

water, or air. All these factors can contribute to poor system performance and will reduce the life of the

liftgate and lifgate components. If the fluid appears to be in poor condition, take the following steps to

change the oil.

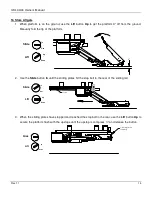

1. Lower gate to ground.

2. Remove the cover from the pump and motor box and locate the oil drainage bolt (6mm hex bolt)

located at the bottom of the tray and let the fluid drain out of the reservoir and into an approved

container. Screw the oil drainage bolt back.

3. Unscrew the oil filler cap. Use a good quality fluid based on your location; refer to the recommended

fluids table. The fluid level should be between marks 5 and 7 when the platform is at ground level.

4. Change oil at least once a year, preferably in the fall before the weather gets cold.

6.3.1

Recommended Hydraulic Fluids

TEMP. RANGE

BRAND

-10 TO 150 F

EXXON

UNIVIS J26

MOBIL OIL

DTE 13M

CHEVRON

AW MV32

ROSEMEAD

MV 150 (32)

-50 TO 150 F

MOBIL

DTE 13M

SHELL

AERO FLUID 4

EXTREME COLD TEMPERATURE:

USE MILITARY SPEC:

MIL H5606

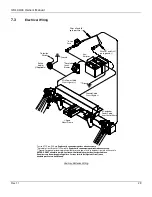

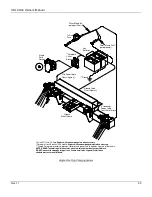

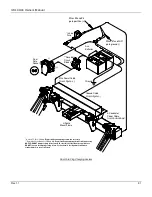

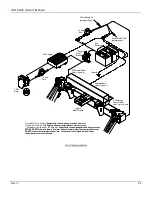

Hydraulic

connections

Suction filter

in oil tank

Oil filler cap

S5 Shift valve

Motor Studs

Motor Solenoid

Pressure Gauge plug

Below valve block:

Oil drainage screw 6mm hexagon

Tray lock bolt

Содержание ILSL 33/44

Страница 1: ...ILSL 33 44 OWNERS MANUAL 11 14 ...

Страница 11: ...ILSL 33 44 Owner s Manual Rev 1 1 11 NOTES ...

Страница 21: ...ILSL 33 44 Owner s Manual Rev 1 1 21 NOTES ...