56

Fig.12.2

USE AND & MAINTENANCE

12.2.5

&OHDQLQJRIWKHÀXH

This should be performed at least twice a year,

at the start of and half-way through winter, and

in any case whenever necessary or provide by

local regulations (Fig.12.2). If there are horizontal

sections, check for and remove any accumulated

DVKDQGVRRWEHIRUHWKHVHEORFNWKHÀRZRIÀXHJDV

&KHFNIRUWKHFRUUHFWVHDOLQJRIWKHFRPSOHWHÀXH

gas duct.

In the case of strong wind or special weather

conditions, the boiler may indicate alarm signals.

This is to be considered quite normal. Reset the

alarm and proceed to ignite the boiler again. In the

event this condition persists in a continuous manner

please contact the authorized service centre.

The failure or inadequate cleaning of the boiler

can affect the safety and generate functionality

problems such as:

poor combustion;

blackening of the glass;

blockage of the burn pot by ash and pellets;

accumulated ash and excessive fouling of the

heat exchanger, with a consequent decline in

HI¿FLHQF\

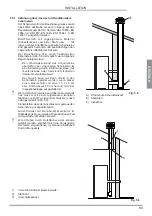

12.2.6 Cleaning of the boiler and heat exchanger

Periodic cleaning of the boiler and heat exchanger

must be carried out solely and exclusively by

authorized personnel, consult to this regard with

the after-sales service.

It is recommended to carry out this operation

only when necessary, keeping under control the

WHPSHUDWXUHRIWKHÀXHJDV

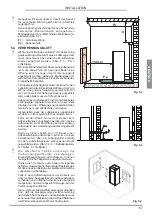

12.3 OPERATIONS TO BE CARRIED OUT

AT THE END OF THE SEASON

It is recommended to use all the pellets present

in the hopper in order to prevent the formation of

condensation, which could cause clogging and

seizing of the feed motor.

The residue of pellets and the sawdust present in

the bottom of the hopper must be removed with the

aid of an aspirator.

,QFDVHRISUHVHQFHRIVDZGXVWLQVLJQL¿FDQWDPRXQW

it is recommended to verify the quality of the pellets

used as power supply for the boiler.

This operation must be carried out when the boiler

is off, disconnecting the power supply.