B-144-12-E

23

10.4 Sizes 52, 53, 55, 56, and 57 Meter Body Assembly Procedure

PRECAUTIONS BEFORE ASSEMBLY

Oval rotors, inner walls of the rotor shafts, inner wall of the measuring chamber, inlet

and outlet ports, and inner surface of the rear cover should be thoroughly washed clean,

completely removing dust, grime and other foreign matter.

①

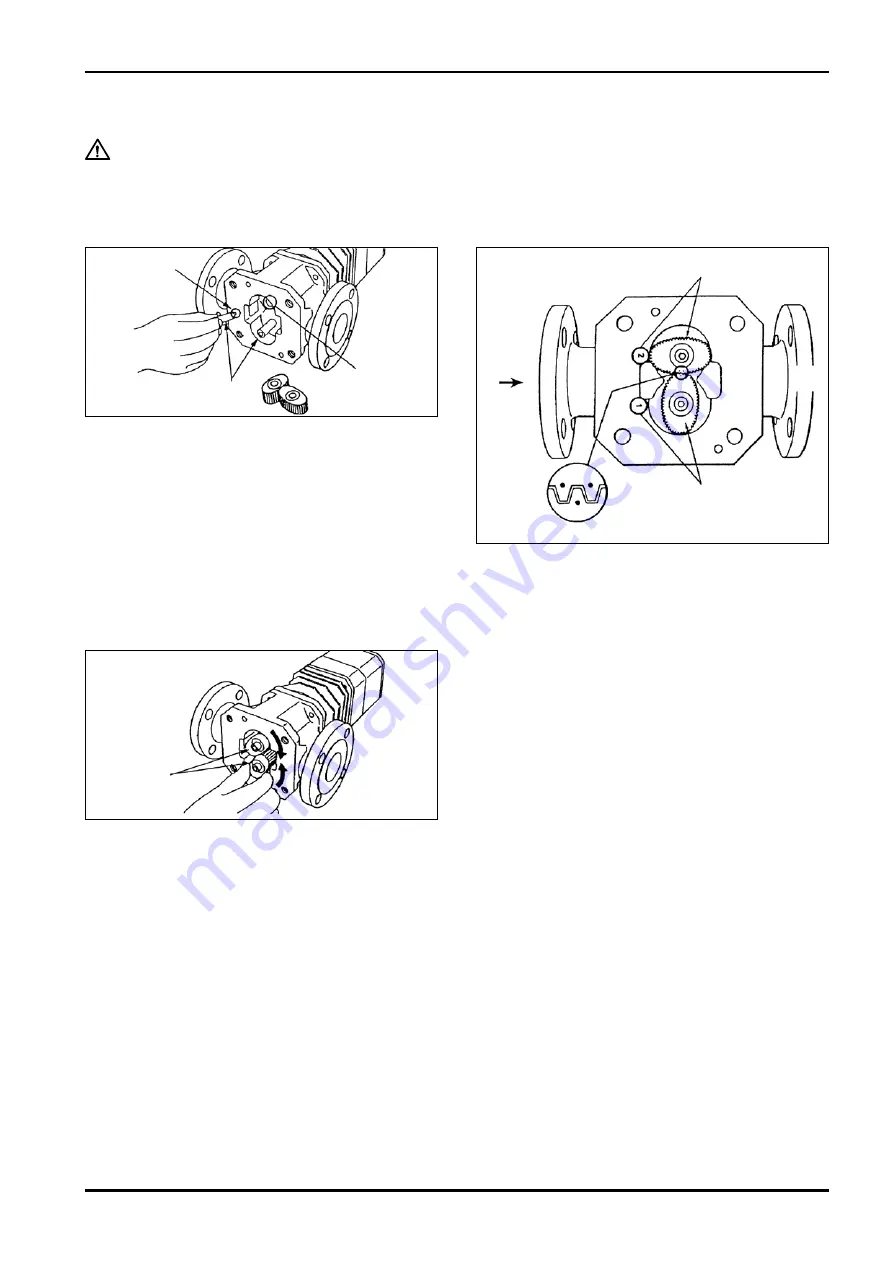

Rotor Shaft Installation

The non-turn pin end of each rotor shaft faces

the register (bottom of the measuring chamber).

Install the shafts, pin end first, into their sockets

on the bottom of measuring chamber (bottom of

meter body), forcing downward while turning each

of them with hands until they are firmly installed in

position.

(Air in the socket may resist to be compressed by

the shafts. So good practice is to hold the shafts

pressed down by hand for some time.)

②

Rotor Installation

Rotor installation is correct if the sides where

signal generating magnets are embedded face

the register (bottom of the measuring chamber)

and the sides with match marks (

・

) (

・・

) face

the rear cover. Carefully install the rotors with the

1st rotor (match mark "

・

") on the shaft with "1"

stamped on the outside of measuring chamber

and the 2nd rotor (match mark "

・・

") on the shaft

with "2" stamped. Ensure that the match marks

are in alignment as shown in the inset.

③

Confirming the Rotor Gear Engagement

Hand rotate the rotors to make sure of correct

gear mesh. At this point, they may be shaky more

or less with the shafts not fixed firmly. Exercise

care not to damage the rotors and inner wall of the

measuring chamber by forcing them to rotate.

Rotors

Non-Turn Pin

Rotors

Shaft Soket

Rotor Shafts

1st Rotor

"1" Marks

Match Marks

IN

Flow

2nd Rotor

"2" Marks

OUT