9

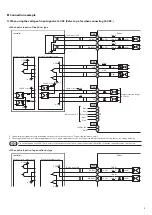

Timing chart

*3

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

CW input

DIR input

CCW input

PLS input

AWO input

Motor operation

Power supply input

ON

OFF

ALM output

Excitation

Non-excitation

Motor excitation

5 µs or more

*1

0.1 s or more

0.1 s or less

0.2 s or less

0.2 s or less

0.2 s or less

0.2 s or less

10 s or less

5 µs or more

5 µs or more

*2

CS input

Base step angle

Step angle set by the driver switch

2-pulse input

mode

1-pulse input

mode

5 ms or more

*1

*1

CW

CCW

CCW

0.2 s or more

*1 The interval for switching the motor direction represents the response time of the circuit. Set this interval to an appropriate time after which the motor will respond.

*2 It varies depending on the moment of load inertia, load torque, starting frequency, and so on.

*3 When cycling the power, turn off the power and wait for the PWR/ALM LED to turn off.

Noise measures

The electrical noise is of two types: One is a noise to invade into the driver

from the outside and cause the driver malfunction, and the other is a noise to

emit from the driver and cause peripheral equipments malfunction.

For the noise that is invaded from the outside, take measures to prevent the

driver malfunction. It is needed to take adequate measures because signal

lines are very likely to be affected by the noise.

For the noise that is emitted from the driver, take measures to suppress it.

z

Measures against electrical noise

There are the following three methods mainly to take measures against the

electrical noise.

•

Noise suppression

y

When relays or electromagnetic switches are used together with the

system, use noise filters and CR circuits to suppress surges generated by

them.

y

Cover the driver by a metal plate such as aluminum. This is effective in

shielding the electrical noise emitted from the driver.

•

Prevention of noise propagation

y

Place the power lines, such as the motor and power supply cables, keeping

a distance of 100 mm (3.94 in.) or more from the signal lines, and also do

not bundle them or wire them in parallel. If the power cables and signal

cables have to cross, cross them at a right angle.

y

Use shielded twisted pair cables of AWG22 (0.3 mm

2

) for power lines and

AWG24 to 22 (0.2 to 0.3 mm

2

) for signal lines.

y

Keep cables as short as possible without coiling and bundling extra lengths.

y

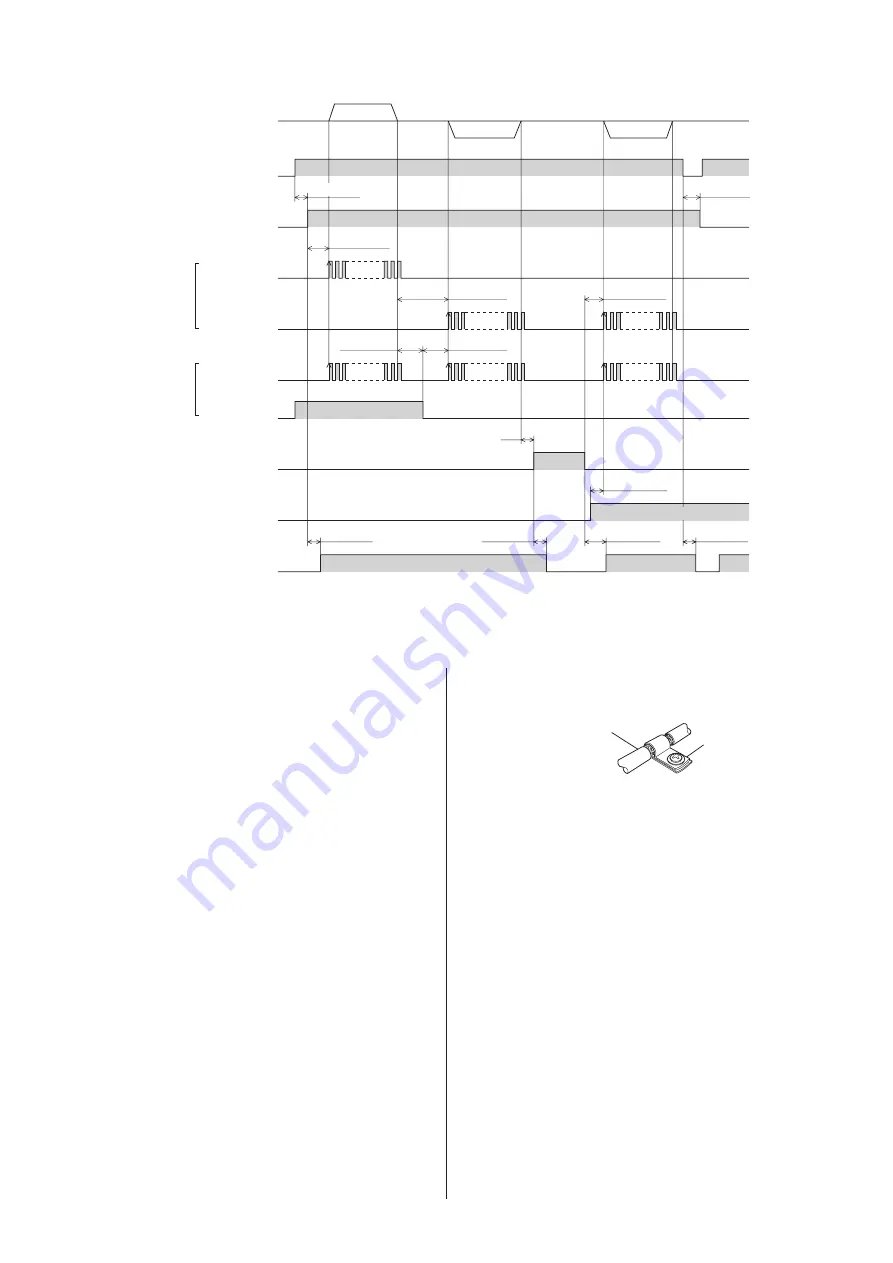

To ground a shielded cable, use a metal cable clamp that will maintain

contact with the entire circumference of the cable. Ground the cable clamp

near the product.

Cable clamp

Shielded cable

y

When grounding PE terminals of multiple drivers to a grounding point,

it becomes more effective to block the electrical noise since impedance

on the grounding point is decreased. However, ground them so that a

potential difference does not occur among the grounding points. An

accessory connection cable (for signal) that includes a ground wire is

provided. Refer to p.12 for details.

•

Suppression of effect by noise propagation

y

Loop the noise propagated cable around a ferrite core. Doing so will

prevent the propagated noise invades into the driver or emits from the

driver. The frequency band in which an effect by the ferrite core can be

seen is generally 1 MHz or more. Check the frequency characteristics of the

ferrite core used. To increase the effect of noise attenuation by the ferrite

core, loop the cable a lot.

y

Use the line driver type, which is less likely to be affected by electrical noise,

for the output circuit of pulse signals. If the pulse signal of the controller is

of the open collector type, use an accessory pulse signal converter for noise

immunity. Refer to p.12 for details.