7

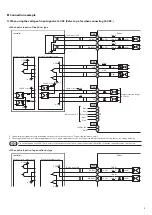

Connector pin assignment

1 2 3

• • • • • •

CN3

12

11

10

1 2

+ -

3 4 5

CN2

CN1

z

CN1 (power supply)

Pin No.

Direction

Signal name

Description

+

IN

POWER

+24 VDC

−

GND

z

CN2 (motor)

Pin No.

Direction

Signal name

Description

1

OUT

MOTOR

Blue motor lead wire

2

Red motor lead wire

3

Orange motor lead wire *

4

Green motor lead wire

5

Black motor lead wire

* This orange lead wire is for 5-phase stepping motor. For 2-phase stepping motor,

do not connect anything to the pin No.3 since there is no orange lead wire.

Connector pin assignments vary depending on the motor. For details,

refer to "Connecting the motor" on p.4.

z

CN3 (I/O signals)

Pin No.

Direction

Signal name

Description

1

IN

PLS (CW)

+

Pulse (CW pulse) input *

2

−

3

DIR (CCW)

+

Rotation direction (CCW

pulse) input *

4

−

5

AWO

+

All windings off input

6

−

7

CS

+

Step angle switching input

8

−

9

OUT

ALM

+

Alarm output

10

−

11

TIM

+

Timing output

12

−

* These inputs serve as the pulse input (PLS) and rotation direction input (DIR) in

the 1-pulse input mode, or CW pulse input (CW) and CCW pulse input (CCW) in

the 2-pulse input mode.

Applicable connector

Type

Application

Model

Connector housing

For power supply (CN1)

51103-0200 (Molex)

For motor (CN2)

51103-0500 (Molex)

For I/O signals (CN3)

51103-1200 (Molex)

Contact

−

50351-8100 (Molex)

Applicable crimping tool

−

63811-8100 (Molex)

Type

Application

Applicable lead wire

y

For power supply (CN1)

AWG22 (0.3 mm

2

)

Outer sheath diameter:

ø1.15 to 1.8 mm (ø0.045 to 0.071 in.)

Strip length of the insulation cover:

2.3 to 2.8 mm (0.091 to 0.11 in.)

y

For motor (CN2), for I/O signals (CN3)

AWG24 to AWG22 (0.2 to 0.3 mm

2

) *

Outer sheath diameter:

ø1.15 to 1.8 mm (ø0.045 to 0.071 in.)

Strip length of the insulation cover:

2.3 to 2.8 mm (0.091 to 0.11 in.)

* About the connector for motor (CN2) of the

CVD228

and

CVD524

, use lead wires of AWG22

(0.3 mm

2

).

y

For the I/O signals cable, use a twisted pair cable.

y

Keep the wiring distance as short as possible [less than 2 m (6.6 ft.)] to

suppress the effect of noise.

For the motor of the frame size 20 mm (0.79 in.) [

PKP213

type], since

the wire diameter of the motor cable is AWG26 (0.14 mm

2

), it is too

thin to fit in the supplied connector for motor. Provide the cable of

AWG24 to AWG22 (0.2 to 0.3 mm

2

) yourself, and connect by using it.

Cable of AWG24 to AWG22

PKP213

Driver

Connecting the power supply

Use a power supply that can supply the following current capacity.

When the power is turned on, the PWR/ALM LED will be lit in green.

Driver model

Input power supply

voltage

Power supply

current capacity

CVD205

+24 VDC±10%

0.5 A or more

CVD215

1.3 A or more

CVD223

2.0 A or more

CVD228

3.0 A or more

CVD512

1.7 A or more

CVD518

2.8 A or more

CVD524

2.7 A or more

y

When connecting, pay attention to the polarity of the power supply.

Reverse-polarity connection may cause damage to the driver.

y

Have the connector plugged in securely. Insecure connection may

cause malfunction or damage to the driver.

y

When unplugging the connector, do so while spreading the latches

on the connector a little.

y

When cycling the power or plugging/unplugging the connector,

turn off the power and wait for the PWR/ALM LED to turn off.

y

Separate I/O signals cable at least 100 mm (3.94 in.) from

electromagnetic relays and other than inductance loads.

Additionally, route I/O signals cable perpendicular to power supply

cable and motor cable, rather than in a parallel fashion.

y

Do not route the power supply cable in the same conduits as other

power supply lines and motor cable.

y

If the motor cable or power supply cable generates an undesirable

amount of noise depending on the wiring or configuration, shield

the cable or install a ferrite core.