4 Installation

-

13

-

4.3 Load installation

When installing the load to the motor or gearhead, ensure that the motor output shaft

or gearhead output shaft and load shaft are aligned with each other. Optional flexible

couplings are available (sold separately).

The output shaft of the round shaft type and geared type is provided with a flat. Use

double point screws on the flat and provide reliable locking to prevent idle rotation

of the load.

The combination type gearhead output shaft is provided with a key groove. A key

groove must also be provided on the side of the load to be installed. Use the attached

key to lock it in position.

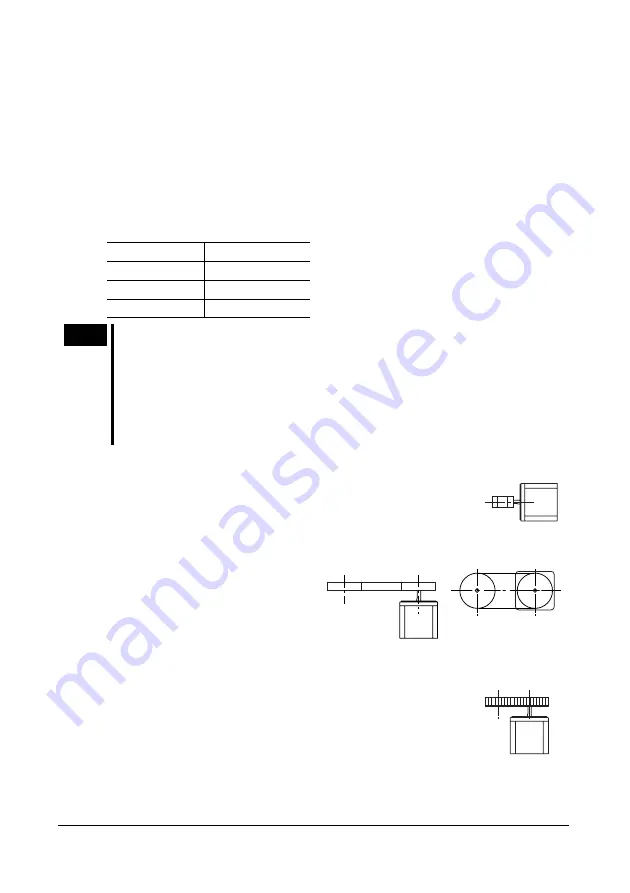

Unit model

Key dimensions

AXH230KC-

4 mm (0.1575 in.)

AXH450KC-

5 mm (0.1969 in.)

AXH5100KC-

6 mm (0.2362 in.)

Note

•

When connecting the motor (gearhead) with a load, care must be taken to

ensure adequate alignment, belt tension and pulley parallelism. The

coupling and pulley locking screws must be clamped firmly in position.

•

To install a coupling or pulley to the motor output shaft or gear output shaft,

sufficient care must be taken not to damage the output shaft and bearing.

•

Do not modify or machine the motor (gearhead) output shaft. It may damage

the bearing, which may result in motor (gearhead) failure

Direct connection of coupling

Ensure that the motor (gearhead) output shaft and load shaft are

aligned with each other.

Belt connection

Ensure that the centerlines of the

motor (gearhead) output shaft and load

shaft are parallel with each other, and

that the line connecting the centers of

both pulleys and shaft are at a right

angle to each other.

Gear connection

Provide correct engagement with the center of the gear tooth

surface to ensure that the motor (gearhead) output shaft and gear

shaft are parallel to each other.