OPTIMUM

M A S C H I N E N - G E R M A N Y

Version 1.0.1 2014-05-16

Page 113

Original operating instructions

TU2506 | TU2506V | TU2807 | TU2807V

GB

3.9

Safety

Use the lathe only under the following conditions:

The lathe is in proper working order.

The lathe is used as prescribed.

The operating manual is followed.

All safety devices are installed and activated.

All failures should be eliminated immediately. Stop the immediately in the event of any abnor-

mality in operation and make sure it cannot be started-up accidentally or without authorisation.

Notify the person responsible immediately of any modification.

"For your own safety during operation“ on page 92

3.10

Operating elements for feed

3.11

Tool holder

Clamp the lathe tool into the tool holder.

The lathe tool needs to be clamped as short and tight as possible when turning in order to be

able to absorb the cutting force well and reliably during the chip formation.

Adjust the height of the tool. Use the tailstock with the center point in order to determine the re-

quired height. If necessary, put the steel washers beneath the tool to achieve the required

height.

3.12

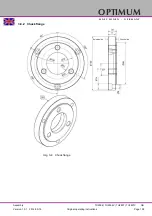

Lathe chuck

The workpieces must be clamped firmly and securely onto the lathe before they are machined.

The clamping force should be tight enough to ensure that the workpiece is moved correctly, but

not sotight that it is damaged or deformed.

WARNING!

Do not clamp any workpieces that exceed the permitted chucking capacity of the lathe

chuck. The clamping force of the chuck is too low if the clamping range is being

exceeded. The clamping jaws might be getting loose.

Infeed speed

Metric thread

Inch thread

Lead screw nut disengaged

(feed deactivated)

Lead screw nut engaged (feed activated)

Feed direction

mm

n/1"