OPTIMUM

M A S C H I N E N - G E R M A N Y

Assembly

Version 1.0.1 2014-05-16

Page 110

Original operating instructions

TU2506 | TU2506V | TU2807 | TU2807V

GB

3.8.3 Mounting instruction of collet chuck holder

Mounting of collet chuck holder 344 1305 on your lathe.

Proceed as follows.

Mark out the position of the jaw chuck

at the spindle flange before disman-

tling with an e.g. felt-tipped pen. This

allows an identical reassembly.

Dismantle the jaw chuck.

Clean all faces of the spindle nose and

of the collet chuck holder extremely

thoroughly.

Dismantle the thread pins of the jaw

chuck and screw in the thread pins into

the collet chuck holder.

Measure the run out of the spindle

flange. Mark out the greatest positive

rash of the dial gauge at the spindle

flange with an e.g. felt-tipped pen.

Attach the collet chuck holder to the

spindle flange, tighten the nuts easily.

Pull in the nuts stepwise ones and uni-

formly alternating at least three times

in succession (you receive the run out

possible for best only this way).

Measure the run out of the collet chuck

holder at the conical surface.

Position the collet chuck holder by

turning each 120° at the spindle flange

to the highest run out precision is

achieved.

Mark out the position of the highest cir-

cularity accuracy of spindle flange with

collet chuck holder and assemble after

this the collet chuck holder on the

highest circularity accuracy position.

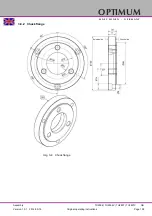

Img.3-5:

Collet chuck holder 344 1305 without union

nut.

Spindle flange

(short-taper seat)

Measuring position

Set screw

Measuring

position