22

1. RMF555525 - Foam Filter

BXI020118B / BXI030118B - 2 or 3hp Motor Assembly (1)

AXB999110 Dust Sentry™ Drum Level Indicator (1)

FGA000000 - Filter Ground Wire (1)

WBP000000 - Control Box / Strobe Light (1)

2. BHX001801 - Fan Housing (1)

3. SCX001801A - Cyclone (1)

4. SEX350600 - Drum Lid (1)

5. RHL000001 - Lid Clamp guards (4)

6. SES350000 - 35 Gal. Steel Drum (1)

7. AFL990001 - Drum Latches (4)

8. RHC000000 - Drum Casters (3)

9. RFG010000 - Leg Gusset (3)

10. VRM990425 - Foam Leg Grip (1)

11. VRT010049 - Front Leg (1)

12. FXX001801 - Front Drum Lid Bracket (1)

13. RHC000005 - Front Leg Caster (1)

14. BSS131000 - Silencer (1)

15. BSC130000 Drop In Foam Filter Silencer (1)

16. FCS133695HF - 13 x 36 HEPA Media Filter

17. AFJ051602 - J Hooks (4)

18. AFT000001 - Thumb Nuts (5)

19. FPZ000013 - 13” Plastic Dust Bin (1)

20. Plastic Axle Protector (1)

21. RSR330625 - Threaded Rear Axle (1)

22. YSS516185 - Threaded 18” Filter Rod (2)

23B. YSS516010 - Threaded 10” Filter Rod (1)

24. VRH051618 - Filter Rod Coupler (2)

25. RBX000000 - Filter Bottom Bracket (1)

26. VRT010047 - Rear Leg (2)

27. STP000003 - Handle (2)

27A. VRM425075 - Flat Handle Grip (2)

28. FXX001802 - Rear Drum Lid Bracket (2)

29. AFS125016 - Rear Leg Threaded Tube Connect (2)

30. AFB038001 - Eye Bolt (2)

31. VRW010002 - 10” Wheels (2)

32. RSP092069P - Drum Liner Holder (1)

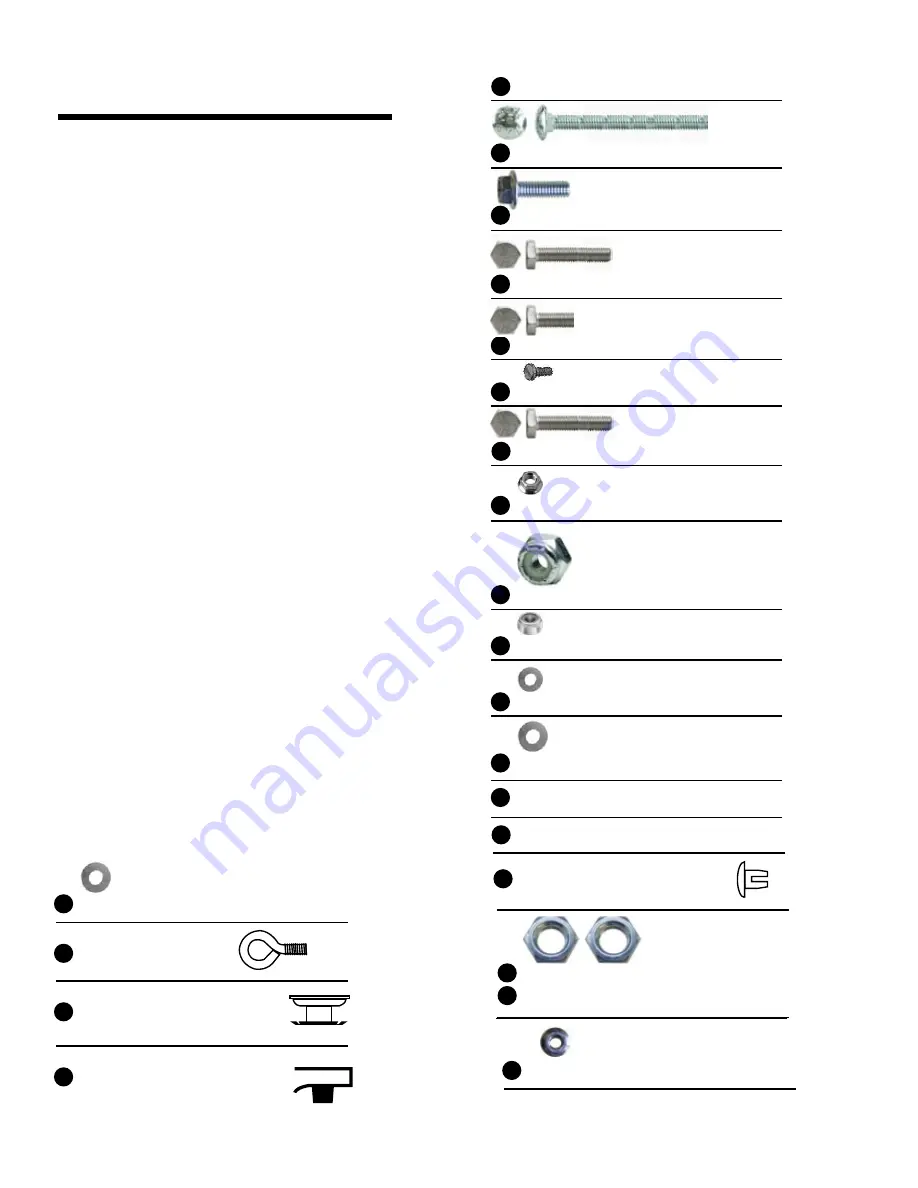

L

AFW180000 - Flat Washer USS 5/16” (28)

M

RGZ025050 - Gasket 1/2” (25 ft.)

N

RGZ516100 - Gasket 1” (7 ft.)

O

PBH000600 - Plastic Push Pin (6)

K

AFW025000 - Flat Washer USS 1/4” (41)

J

AFT901032 - Nylock Nut 10 - 32 (8)

I

AFT900058 - Nylock Nut 5/8 - 11 (2)

H

AFT000005 - Whiz Lock Nut 1/4” (31)

F

AFS103238 - Screw 10 - 32 x 3/8” Pan Head (8)

E

AFS015800 - Bolt 1/4” - 20 x 1/2” Hex Head (10)

D

AFS015920 - Bolt 1/4” - 20 x 3/4” Hex Head (6)

B

AFB025175 - Carriage Bolt 1/4”- 20 x 1.75” (9)

Hardware List

A

ASC000125 - Caulk Single (1)

G

AFB155175 - Bolt 5/16”-18 x 3/4” (14)

P

AFT058011 - Jam Nut - 5/8” 11 (2) - 1/4” high

Q

AFT050811 - Hex Nut - 5/8” 11 (2) - 1/2” high

C

AFB155155 - Flange Bolt 5/16”- 18 x 1” H GR5 (7)

System Contents / le contenu

du système

S

AFW050000 - Flat Washer USS 1/2” (3)

T

AFB038001 - Eye Bolt (2)

U

AFS125016 - Rear Leg Threaded

Tube Connect (2)

V

AFT010916 - U-Spring Nut

#10 x 9/16”

R

AFT155175 - Whiz Lock Nut 5/16” (7)