ENGLISH

Cod. 710.0151.01.00 Rev0B – 08.2012

9 - 66

4. MAINTENANCE, TROUBLESHOOTING AND DISMANTLING

4.1 MAINTENANCE

Before attempting any maintenance operation, make sure that:

1. No parts of the system is under pressure.

2. No parts of the system is electrically powered.

WEEKLY OR EVERY 40 HOURS OF OPERATION

Verify the temperature on the control panel display.

visually check if the condensate is drained regularly.

MONTHLY OR EVERY 200 HOURS OF OPERATION

Clean the condenser with a compressed air jet, taking care not to damage the cooling battery

aluminium wings.

At the end of the above mentioned operations, check if the dryer is working properly.

YEARLY OR EVERY 2000 HOURS OF OPERATION

Check if the flexible tube used for condensate drainage is damaged and replace it if necessary.

Check if all connecting pipes are properly tightened and fixed.

At the end of the above mentioned operations, check if the dryer is working properly.

4.2 TROUBLESHOOTING

NOTE: FOLLOWING BEHAVIORS ARE NORMAL CHARACTERISTIC OF OPERATION AND NOT TROUBLES:

•

Variable speed of the fan.

•

Visualization of message ESA in case of operation without load.

•

Visualization of negatives values in case of operation without load.

Troubleshooting and eventual control and/or maintenance operations must be performed

by qualified personnel.

For maintaining the refrigerating circuit of the machine, contact a refrigeration engineer.

TROUBLE

DISPLAY

POSSIBLE CAUSE

REMEDY

W

A

T

ER

I

N

T

H

E

SYST

EM

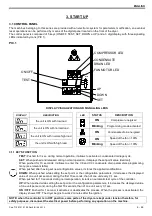

Control panel

display is

blank

No power in the line.

Restore the power in the line.

Problems with cabling.

Check cabling; if the trouble persists, replace it.

Problems with the electronic control board.

Check the electronic control board; if the trouble persists,

replace it.

The dryer is off.

Turn it on by pressing the ON/OFF switch for 1 second.

Dryer in stand-by.

Wait 2 minutes after the dryer is switched on.

Compressed air inlet/outlet inverted.

Check if the compressed air inlet/outlet is connected

properly.

The flow rate and/or temperature of the air

entering the dryer are higher than the

nominal values.

Restore the nominal conditions.

The ambient temperature is higher than the

nominal values.

Restore the nominal conditions.

The condenser is dirty.

Clean the condenser.

Condensate drain is not functioning.

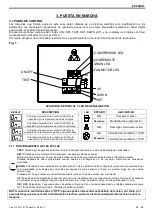

Clean the condensate drainage system pre-filter. (Pic.3)

Replace the coil of the drainage solenoid valve if burned.

Clean or replace the drainage solenoid valve if

clogged/jammed.

Check the C8 and C9 parameters of the electronic control

board; if the trouble persists, replace it.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

Содержание EL 108

Страница 2: ......

Страница 50: ...Cod 710 0151 01 00 Rev0B 08 2012 48 66...

Страница 51: ...Cod 710 0151 01 00 Rev0B 08 2012 49 66 1 1 1 3 C IP 42 1 2 2 2 1 8 50 90 12...

Страница 55: ...Cod 710 0151 01 00 Rev0B 08 2012 53 66 3 1 4 1 2 3 3 250 3A AC 15 3 3 2 3 3 1 2 3 4 2 5 6 7 ON OFF 10...

Страница 56: ...Cod 710 0151 01 00 Rev0B 08 2012 54 66 4 4 1 1 2 40 200 2000 4 2 ESA 1 ON OFF 2 3 C8 C9...

Страница 57: ...Cod 710 0151 01 00 Rev0B 08 2012 55 66 1 C8 C9...

Страница 58: ...Cod 710 0151 01 00 Rev0B 08 2012 56 66 4 4 3...

Страница 64: ...Cod 710 0151 01 00 Rev0B 08 2012 62 66 Cod 714 0170 07 00 Rev 00 EL 280 340 230V 1Ph 50Hz...

Страница 69: ......