ENGLISH

Cod. 710.0151.01.00 Rev0B – 08.2012

10 - 66

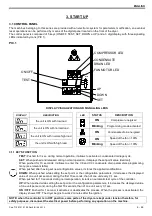

TROUBLE

DISPLAY

POSSIBLE CAUSE

REMEDY

W

A

T

ER

I

N

T

H

E

SYST

EM

Problems with cabling or with the electronic

control board.

Check the cabling and the electronic control board, if the

trouble persists, replace them.

Activation of compressor’s internal thermal

protection.

Wait one hour and check again. If the fault persists: stop

dryer and call your local distributor.

Problems with the electrical components of

the compressor.

Check the electrical components of the compressor.

Defective compressor.

Replace the compressor.

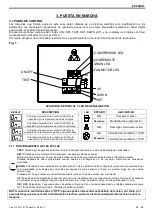

The flow rate and/or temperature of the air

entering the dryer are higher than the

nominal values.

Restore the nominal conditions.

The ambient temperature is higher than the

nominal values.

Restore the nominal conditions.

The condenser is dirty.

Clean the condenser.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

Fan pressure switch defective or burned out

(if present).

Turn off the dryer and call your local distributor.

High pressure switch defective or burned out

(if present).

Turn off the dryer and call your local distributor.

Gas leakage in the refrigerating circuit.

Turn off the dryer and call your local distributor.

Defective fan.

Replace the fan.

Protection fuse burned out (if present).

Replace the fuse.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

Gas leakage in the refrigerating circuit

without load.

Turn off the dryer and call your local distributor.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

Series of alarms very close to each other.

Call your local distributor.

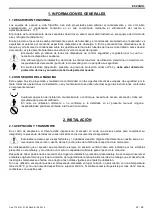

L

O

W

PR

ESSU

R

E

IN

T

H

E

L

IN

E

Ice formation in the evaporator.

Check the probe; if the trouble persists, replace it.

Check the electronic control board; if the trouble persists,

replace it.

Contact our Service Centre to check the gas charge.

Clog.

Check if the compressed air inlet/outlet is connected

properly.

Check if the connecting tubing is clogged; in case proceed

accordingly.

Check if any valves are closed.

Check the condition of any filter.

Air flows continuously through the

condensate drainage.

Drainage solenoid valve jammed, clean or replace it.

Verify the condensate drainage times set on the electronic

control board (C8 and C9).

Check the signal from the control board: if it is continuous,

replace the control board.

IMPORTANT:

The temperature control probe is extremely delicate. Do not remove the probe from its position. In

case of any kind of problem, please contact your “Service Centre”

Содержание EL 108

Страница 2: ......

Страница 50: ...Cod 710 0151 01 00 Rev0B 08 2012 48 66...

Страница 51: ...Cod 710 0151 01 00 Rev0B 08 2012 49 66 1 1 1 3 C IP 42 1 2 2 2 1 8 50 90 12...

Страница 55: ...Cod 710 0151 01 00 Rev0B 08 2012 53 66 3 1 4 1 2 3 3 250 3A AC 15 3 3 2 3 3 1 2 3 4 2 5 6 7 ON OFF 10...

Страница 56: ...Cod 710 0151 01 00 Rev0B 08 2012 54 66 4 4 1 1 2 40 200 2000 4 2 ESA 1 ON OFF 2 3 C8 C9...

Страница 57: ...Cod 710 0151 01 00 Rev0B 08 2012 55 66 1 C8 C9...

Страница 58: ...Cod 710 0151 01 00 Rev0B 08 2012 56 66 4 4 3...

Страница 64: ...Cod 710 0151 01 00 Rev0B 08 2012 62 66 Cod 714 0170 07 00 Rev 00 EL 280 340 230V 1Ph 50Hz...

Страница 69: ......