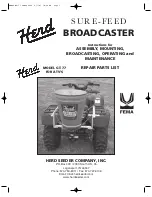

Brush assembly

mounting screw

Brush assembly

Brush bracket 2

Brush

Brush bracket 1

Hexagon socket head setscrew

M2.6 10

Plain washer

Spring washer

Must not hit

Passage plate

Passage plate setscrew

– 16 –

7. Replacing Parts

7.1 Replacing the Brush

Turn off the power switch before performing check

and adjustment work.

If the tip of the brush has worn to such degree that the brush can no

longer brush away screws in an abnormal posture, replace with a new

brush.

• Turn the feeder power switch on, then off to position the brush as

shown at right and then remove the brush assembly. (Have the brush

assembly positioned to ease the work of removing the mounting

screw.)

• The brush assembly can be disassembled as shown at right.

• To reassemble the brush assembly, reverse the removal procedure.

• W hen the reassembly is completed, check to make sure that the front

of the plastic part of the brush won’t the passage plate when the

brush assembly operates. A clearance of 0 is ideally recommended.

• For adjustment instructions, see 5.4, “Brush Check and Adjustment.”

7.2 Replacing the Passage Plate

Turn off the power switch before performing check

and adjustment work.

W hen using screws of different nominal diameters, replace the

passage pates for both the rail assembly and the cutting disc assembly.

• Remove the passage plate setscrew and then remove the passage

plate.

• Keep the setscrew in a safe place.

• Install the passage plate in position with reference to the drafts on its

both sides.

• After the adjustment, the passage pate requires adjustment to meet

the kind of screw to use.

For adjustment instructions, see 5.5, “Passage Plate Check and

Adjustment.”

Caution

Caution