21

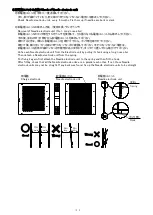

●針電極ユニットの点検

/

Check of Needle electrode unit

◎針電極ユニットを半年に一度点検してください。

また、針が曲がっていたり、針と板が平行になっていない場合には修正してください。

Check Needle electrode units every 6 months. Fix them up if needles are bent or slant.

◎針電極ユニットの取外し方法

(使用工具:ラジオペンチ)

Removal of Needle electrode unit (Tool : Long-nose plier)

針電極ユニットのフック部をラジオペンチを使用して、引っ張りながら電極ユニットから取外してください。

その後、ばねのフック部分から針電極ユニットを取外してください。

取付けるときは、ばねに針電極ユニットを取付けてから、フック部を取付けてください。

取付け後、隣り合っている板と平行になっているか確認してください。平行になっていない場合は、

針電極ユニット自体が曲がっている可能性がありますので、まっすぐに直してから取付けてください。

Unfix each Needle electrode unit from the Electrode unit by pulling its hook using a long-nose plier.

Then detach a Needle electrode unit from the spring.

For fixing it again, first attach the Needle electrode unit to the spring and then fit the hook.

After fitting, check that all the Needle electrode units are in parallel each other. If not, those Needle

electrode units may not be straight. If any bent was found, fix up the Needle electrode units to be straight.

針電極ユニット

Needle electrode unit

荷電極

Charge electrode

針電極ユニット

Needle electrode unit

Spring

ばね

Hook

フック部

Parallel

Wrong

Good

long

short

長い

短い

Wrong

Good

Parallel

平行

平行