13

●運転条件設定

/Setting of operating condition

①電源を供給してください。

POWER

ランプ(乳白)が点灯することを確認してください。

操作パネル表示部に現在の運転積算時間が表示されます。(出荷時“

0

”を表示します)

Supply power to the unit. Make sure that the POWER LED (opaque white) lights up.

Display shows the current cumulative operation time (

“

0

”

is displayed on delivery)

パラメータ設定

Parameter setting

○現在の運転積算時間が表示されている状態から、

SET

ボタンを押してください。

運転中はパラメータの設定はできません。

SET

ボタンは、無効となります。

○

Press SET button in a state where the current cumulative operation time is displayed.

No parameter setting is enabled during operation and SET button is disabled.

以下の順序でパラメータが表示されます。

SET

ボタンを押すことにより、次パラメータへ

移動します。

変更したいパラメータを表示させ、

UP

ボタン・

DOWN

ボタンで設定値を変更し、

SET

ボタンを押す

ことによってパラメータの変更が決定されます。

Parameters will be indicated in the following order. Press SET button to move to the next

parameter. Display a parameter to change and set a value using UP and DOWN buttons.

Save the parameter by pressing SET button.

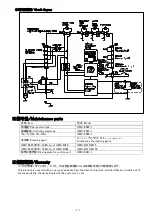

・高電圧の設定

[

表示:

F1]

初期設定:

8

設定範囲:

7

、

8

、

9

説明:高電圧出力を切り替えます。

各電極への高電圧出力値を変更することにより、オイルミストの捕集量、メンテナンス

期間が変わります。

水溶性オイルミストは、導電性が高いため

ALARM

ランプが点滅、または点灯することが

あります。そのような場合は高電圧の出力を下げてご使用ください。

水溶性オイルミストを吸引する場合は、各電極の高電圧の出力値を

-7

kVでのご使用を

推奨します。

・

High voltage setting

[F1] Initial setting: 8 Setting range: 7, 8 or 9

This is to change over high voltage output level.

According to the output value to each electrode, collection amount of oil mist and

maintenance interval change.

As to water-soluble oil mist, the electrode check lamp may blink or light due to its high

electric conductivity. In such case, lower the high voltage output level.

It is recommended to set the output value of each electrode at -7kV for collecting

water-soluble oil mist..

・

高電圧

High-voltage

オイルミスト

捕集量

Collection

amount

メンテナンス

期間

Maintenance

interval

適用オイルミスト(参考)

Applicable oil mist

Approx.

-9 kV

多い

Large

短い

Short

工場出荷時

設定

Factory setting

Approx.

-8 kV

中

Average

中

Average

水溶性オイルミスト

吸引時推奨設定

Recommended setting

for water-soluble oil mist

Approx.

-7 kV

少ない

Small

長い

Long

油性オイルミスト

粒子径が小さい

オイルミストが多量

導電性が低い

Oil-based oil mist

Particle size is small

Large mist volume Low conductivity

水溶性オイルミスト

粒子径が大きい

オイルミストが少量

導電性が高い

Water-soluble oil mist

Particle size is large

Small mist volume High conductivity