LogBox-DA Datalogger

NOVUS AUTOMATION

5/7

INPUT CONNECTIONS – CHANNEL 1

The following figures show connections for the various input types

accepted in channel 1. No jumper is required to adjust the channel 1

input type (the circuit is reconfigured automatically according to the

input type selected).

INPUT CONNECTIONS – CHANNEL 2

For adequate use of channel 2, set internal J1 and J2 positioning

according to the input signal chosen, as shown in the table below

(factory default is 4-20mA / 0-20mA signals).

Input signal

J1 Position

J2 Position

4-20 mA / 0-20 mA

A

A

0-10V

B

B

0-50 mV

C

C

Table 1 – J1 and J2 positioning

The following figures show connections for different types of signals

applied to channel 2.

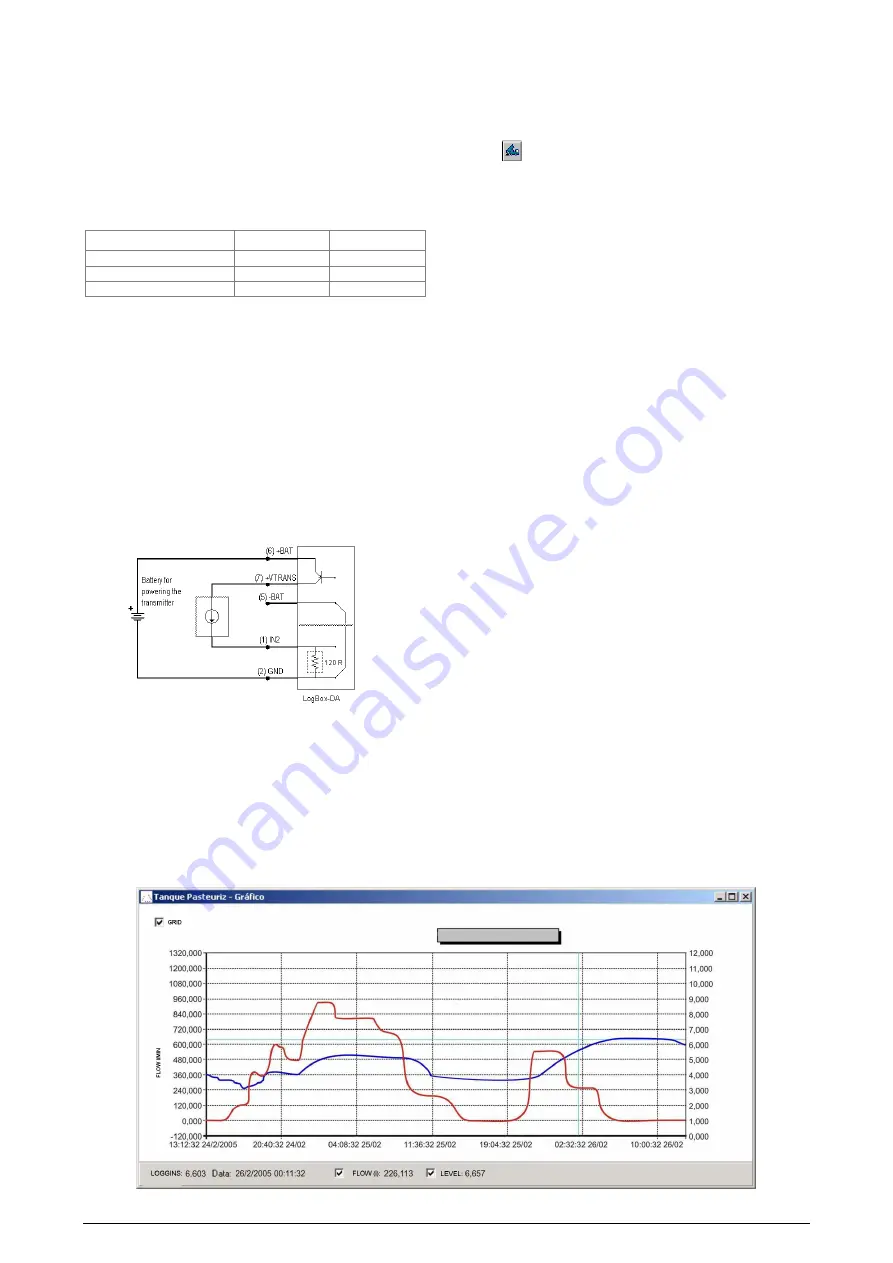

EXTERNAL BATTERY SWITCH

The example below shows the usage of the external battery switch

for commanding the power supply of external devices.

- Channel 2 is configured to 4-20mA input signal. A battery is used to

provide power to the 4-20 mA loop. The battery switch “turns on” the

power to the loop a moment (defined in the configuration) before the

measurement is taken, enabling the transmitter (pressure,

temperature, etc) to start up and stabilize the output. This approach

saves the battery energy, as the power is turned on only when

required (before each measurement).

Fig. 13

– Example of the battery switch powering a transmitter.

INSTALLATION RECOMMENDATIONS

•

Signal wires should be installed in grounded conduits and away

from power or contactor wires.

•

Installing RC filters (47

Ω

and 100nF, serial) is strongly

recommended at contactor coils or any other inductors.

•

System failure should always be taken into account when

designing a control panel to avoid irreversible damage to

equipment or people.

OFFLOADING AND DATA VISUALIZATION

TRANSFERING RECORDS

Transferring the data to a PC is accomplished by clicking on the

button

in the LogChart II software. The IR wand must be pointed

to the logger during the process. Data can be collected anytime and

saved in files for future analysis (menu “File Save” or “File Save as”).

While in offloading process, a progress bar is displayed. The offload

time is proportional to the amount of data being transferred (number

of records in memory).

After data transfer is completed, the

Graph

window is displayed.

NOTE

: The logging is not stopped during the data offload process.

The LogChart-II software includes a help section with detailed usage

information.

VISUALIZING THE DATA

Three views are provided for data visualization. The records can be

analyzed in the form of Chart (graph) or Table. A third window, called

General Information

window (

Fig. 15

), shows acquisition details

and logger configuration.

A region of interest in the data can be selected (see item

Gr

aph

Window

, below). The Graph Window can be printed and the

corresponding data exported as text files to other applications, such

as spread sheets.

The same windows are created when the data is read from a

previously saved file.

After the windows are opened, one can save the data to a file (.lch),

print graphs, or export the data from the

General Information

and

Acquisitions Table

windows

to a text file (.txt or .dat).

Graph window

The Graph is a convenient tool for analysis. As one moves the

mouse in the chart area, the time and the value of the records of

each channel are shown in the field located in the bottom of the

window.

Zooming in and out are implemented. They are available in the menu

“View” or in the tool bar as icons. It is possible to select an area by

clicking and dragging the mouse, creating this way a zoom region,

starting at the upper left position of the region of interest.

The graphs can be moved vertically by moving the mouse up or

down while keeping the mouse right button pressed.

Fig. 14

shows the Graph window.

The Graph window is automatically opened after the offload process.

The two other windows (Table and General Information) can be

opened accessing the menu or clicking on the corresponding button.

Fig. 14

– Screenshot showing the graphic visualization of logged data