Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

5

probe

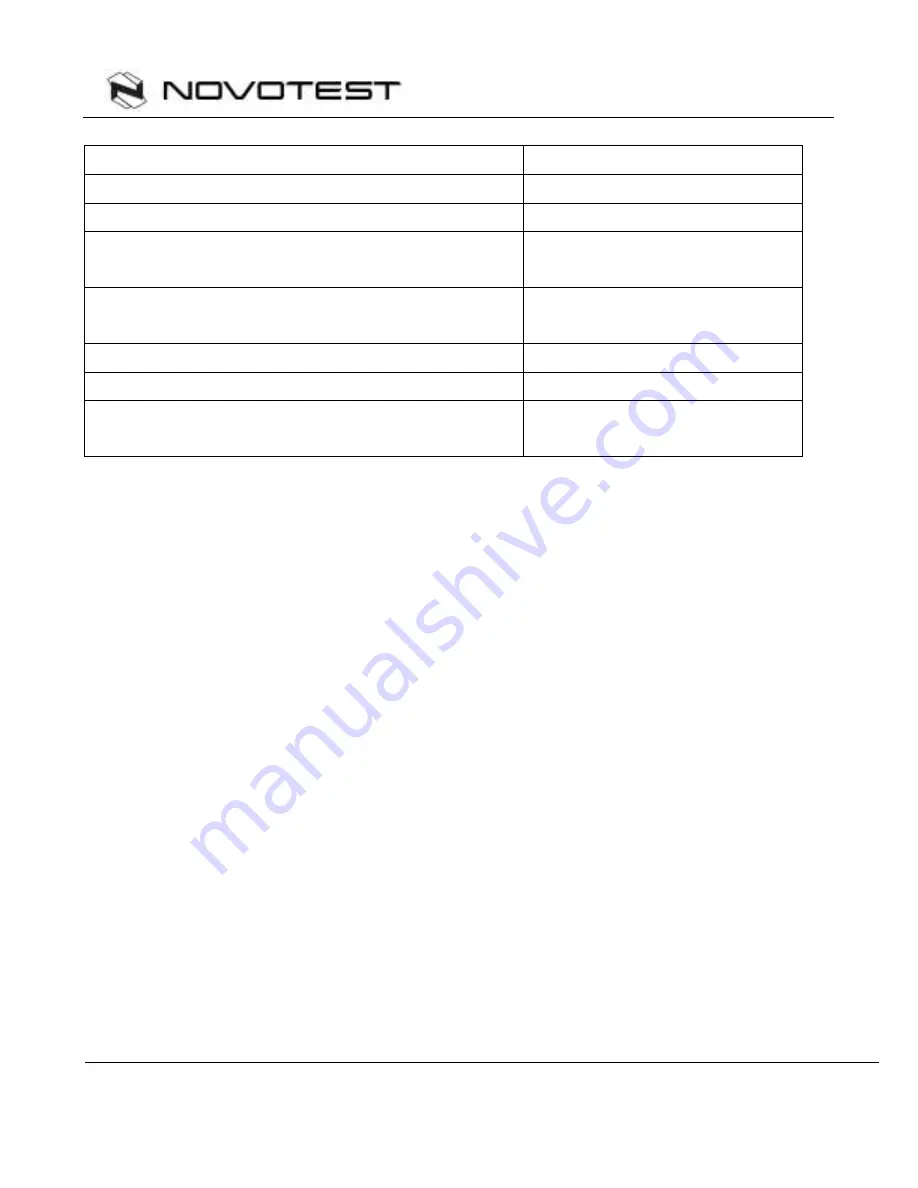

Automatic signaling of defects (AFS)

dual-gate

Setting range of AFS gates

from 0 to 2000

µs

Adjusting thresholds of AFS gates

from 0 to 100 %

высоты экрана

Detection of signals

positive half-wave, radio

mode

Dimensions (WxHxD)

80х162х38 mm;

Weight, not more

250 g (without batteries)

Mean time between failures

not less than - 3000

hours

Ultrasound probes used - ultrasonic piezoelectric transducers for

pulse flaw detectors.

The dimensions of the operating area of the screen is 48 x 74 mm.;

Electrical power is supplied from the following sources:

-

AC power from 100 to 250 V, a frequency of (50 ± 1) MHz;

- AA batteries 1,5 V (3 pcs.).

5 . Operating principle

Operating principle of flaw detector is based on the ultrasonic

contact NDT method, which uses the properties of ultrasonic

vibrations to reflect from the borders between materials with different

acoustic impedance. The ultrasonic transducer emits ultrasonic

impulse into the tested object. Reflected from the defects or the

product surface the echo signals are received by the ultrasonic

transducer. The resulting electrical signals are subject to

amplification, digitization, processing and output to the display.

Displays echoes received by the flaw detector is performing as

scanning of type A (A-scan) as well as images of cross sections of

tested objects in form of B-scan.