Page

34

/

48

general condition of any tool be examined before it is used. Keep your dozer in good repair. Keep handles dry,

clean, and free from oil and grease.

Also refer to the engine manufacturer’s instruction manual for additional

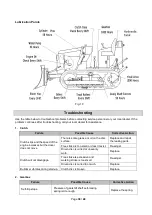

information about engine maintenance. The following chart is based on a normal operation schedule.

Maintenance

Interval

Maintenance Point

Daily Technical

Maintenance

•

Clean the body of the dozer.

•

With the dipstick, check the level of the engine oil in the sump.

It’s

necessary to keep the level between the lower and the upper scale lines.

•

Check whether the coolant in the radiator is sufficient. If necessary, add

more.

•

Check whether the fuel is sufficient. If necessary, refill.

•

Check the track tension. If the sag exceeds 2.5mm, adjust.

i

•

Inspect the outer connections and tighten any loose connections.

•

Check the joints, fittings, and tubes for any leakage. If found, repair or

replace.

•

Verify that the engine components and all parts of the dozer are in proper

working order. If necessary, repair or replace.

•

Lubricate the following points with proper grease.

Track rollers, idlers, and carrier roller.

Pins of the six-action blade.

•

The engine maintenance should be followed according to the technical

maintenance instructions in the 403F-E17T Perkins Operation and Maintenance

Manual.

250-Hour

Technical

Maintenance

•

Clean the air filter.

•

Inspect the brake and steering pedals

’ free strokes. Adjust if necessary.

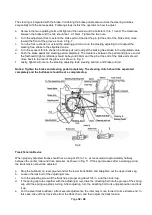

Step 2

. With a

grease gun, add

grease through this

zerk.

Step 1.

Loosen

locking bolts with a

18mm wrench.

Step 2.

Turn the

adjusting nut

clockwise to tighten

and counter-

clockwise to loosen

using a 32mm

wrench.

Step 1

. Open the

cap.

Содержание 40XTD

Страница 12: ...Page 12 48 7 8 9 10 11 12 13 14 15 16 17...

Страница 13: ...Page 13 48 18 19 20 21 22 23 24 25...

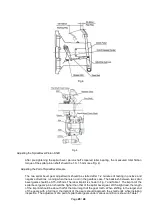

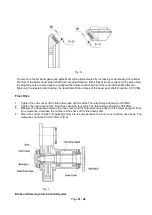

Страница 43: ...43 48 Fig 11 Fig 12...