7

IMPORTANT: If the webbing is not removed, the

condensate will not drain properly and ceiling damage

may occur.

NOTE:

It is recommended that the suction line be insulated

up to the coil inside of the cabinet.

7. Insert the plug (from horizontal drain pan) into the open

and unused drain hole in the drain pan at the bottom of

the unit to block bypass air.

8. Remove the corresponding drain line knockout from the

coil access door to allow access to the horizontal drain.

9. Replace the door and attach the drain line.

Circuit Breaker Cover Installation

The air handler circuit breaker cover is designed to protect

the breakers of an installed heater kit from debris and

condensation.The cover attaches to the breaker recess

of the air handler upper access door using a double-sided

. The heater kit circuit breaker

toggles are still accessible and can be switched with the

cover in place.

• 2-breaker cover for 1.5, 2, 2.5, 3, 3.5 & 4 ton air handlers.

After the heater kit is properly installed, remove the appropriate

knockouts in the upper air handler access door and follow

these instructions to install the breaker cover:

1. Clean any oil, dirt, or insulation fibers from the recess area

of the air handler access door. This step is important for

ensuring the gasket adheres properly to the sheet metal

door.

2. Remove release paper from one side of the gasket

and attach to back side of the breaker cover.

NOTE:

For proper alignment, It is recommended to leave

the center section of the gasket in place when attaching

the gasket to the breaker cover. Remove the center section

after the gasket is applied to the breaker cover.

3. Remove the release paper from the other side of the gasket

and attach to the circuit breaker recess area.

4. Press firmly along all four sides of the cover to ensure

gasket and cover are securely attached to the access door.

Refrigerant Line Connections

WARNING:

NITROGEN

HEALTH

FLAMMABILITY

REACTIVITY

0 Minimal Hazard

1 Slight Hazard

1

0

0

The coil in the air handler is factory shipped with

a nitrogen charge. Avoid direct face exposure

or contact with valve when gas is escaping.

Always ensure adequate ventilation is present

during the depressurization process. Address

any uncertainties before proceeding. Failure

to comply with this warning could result in

equipment damage, personal injury, or death.

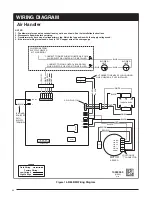

• The installer should make every effort to ensure the field

installed refrigerant containing components of the system

have been installed in accordance with these instructions

and sound installation practices for reliable system

operation and longevity.

• The air handler coil does not contain a refrigerant charge.

Refer to the installation instructions supplied with the

outdoor unit for refrigerant charge information.

• The refrigerant piping to each air handler (or coil) should

be of equal length and size. Run the copper pipes from

condensing unit to a point equidistant between the air

handlers (or coils). Place a tee in the lines at this point. After

the tee (as close to the air handler as practical), reduce

the pipe size to match the piping of the air handler or coil.

• Always refer to the installation instructions supplied with

the outdoor unit for piping requirements. The suction and

liquid lines must be sized in accordance with the condensing

unit specifications. See

for liquid and

suction line locations.

• When connecting refrigerant linesets together, it is

recommended that dry nitrogen be flowing through the

joints during brazing. This will prevent internal oxidation

and scaling from occurring.

• Refrigerant tubing should be routed in a manner that

minimizes the length of tubing and the number of bends in

the tubing. It should be supported in a manner that prevents

it from vibrating or abrading during system operation. Tubing

should be kept clean of foreign debris during installation.

• If precise forming of refrigerant lines is required, a copper

tubing bender is recommended. Avoid sharp bends and

contact of the refrigerant lines with metal surfaces.

• Refrigerant lines should be wrapped with pressure sensitive

neoprene or other suitable material where they pass against

sharp sheet metal edges.

• B64 Series air handlers are charged (with nitrogen) through

service valves on the end of the liquid tube for each circuit.

These must be removed before brazing the line sets.

Orifice Removal & Installation

The orifice installed in the air handler has been sized for use

with the most popularly matched outdoor units. The orifice

size as shipped from the factory is listed on the air handler

rating plate. Perform steps 1 - 9 (

) to confirm that the

orifice size meets the requirements outlined in the outdoor

unit installation manual.

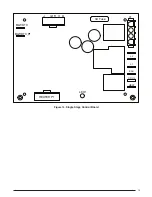

Circuit Breaker

Cover

Circuit

Breakers

Recess

Air Handler A

ccess Door

Figure 5.

Circuit Breaker Cover